Standard Cartridge Seal - ISC2

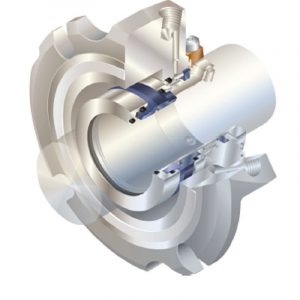

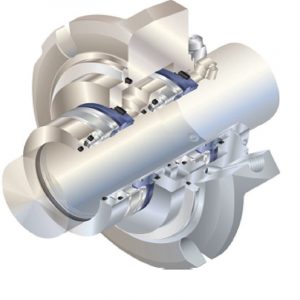

The Standard Cartridge Seal – ISC2 belongs to a series of Flowserve seals which are very popular and are widely used as a mechanical seal for pumps. Its global design allows it to fit literally hundreds of pump models in single and dual, pusher and metal bellows configurations.

The Standard Cartridge Seal – ISC2 is designed to meet all major international standards including ANSI B-73, EN 12756, ISO 3069, JIS and API 682 (ISC2-682 seals) for chemical and general purpose applications.

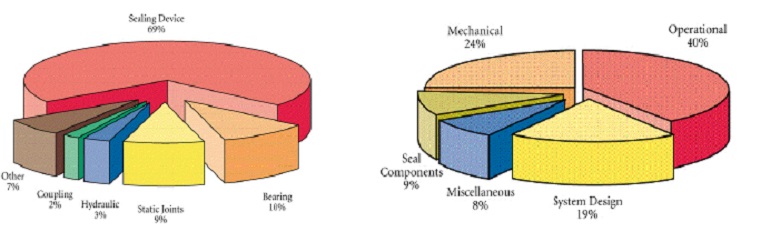

Mechanical Seals are too often blamed for equipment downtime which is why the Standard Cartridge Seal – ISC2 design includes features that specifically address off-design operation and known causes of mechanical seal failure. Flowserve’s innovative approach to thermal management is a key enabler of long-term seal life and less downtime as the mechanical seals can tolerate dry running events.

The Standard Cartridge Seal simplifies the entire sealing life-cycle:

• Installation: robust cartridge design

• Selection: single or dual, pusher or bellows

• Handling: lifting hole on large sizes

• Connecting: clearly-marked ports

• Removing: set screws resist galling

• Repairing: complete support at a local QRC

• Inventory: standardise on ISC2

This Standard Cartridge Seal has a wider application coverage than any other comparable Flowserve seal;

– Size range for pusher design extends from 1.000 to 8.000” (25 to 200 mm) and bellows design extends from 1.000 to 3.750” (25 to 95 mm)

– 62 pre-engineered sizes, 400+ designs are available

– 27 additional basic seal components pre-engineered to fill in 0.250 inch increments throughout the product line

– Pre-engineered designs for hundreds of unique pump models and manufacturers spanning the globe

• Custom sleeves, glands, and collars can be engineered to fit special and custom equipment

Key features of the Standard Cartridge Seal – ISC2 include;

• Chemical – corrosion-resistant standard and optional materials of construction; excellent dual seal performance in hazardous and toxic fluids

• Petrochemical – pusher and bellows seal geometries engineered for a broad range of equipment sizes and operating conditions facilitate plant-wide design standardization

•Water and Wastewater – simple yet robust single pusher cartridge seals are ideal for cost-effective sealing; hard face options improve solids handling

• Biofuels – economical designs are versatile to multiple service types; cartridge installation is easy and the first step toward reliability

• Mining – pusher seals handle light solids up to 10% by weight with hard-on-hard seal faces; smooth geometry reduces opportunity for erosion

• Power – single seals with an optional circulating device provide economical warm water sealing on condensate and circulation pumps

• Unloading terminals – seal face thermal management survives short-term dry run events and batch processes

How we can help you?

Flexachem supply the Standard Cartridge Seal – ISC2 Series for your process pumps into the pharmaceutical, bio-pharma, chemical processing, mineral and ore processing and general industries.

If you have a technical query around the installation of mechanical seals for pumps or have some concerns around mechanical seal failures, why not contact one of our seal specialists below to discuss it in more detail and find out how we can help solve your issues and get your process running again.

Contact our Mechanical Seal Team:

Chris Sheeran (External) – mob: 087 755 9936

Internal Team

Rory Cremin – Tel: 021 461 7213

Tel: 021 461 7200