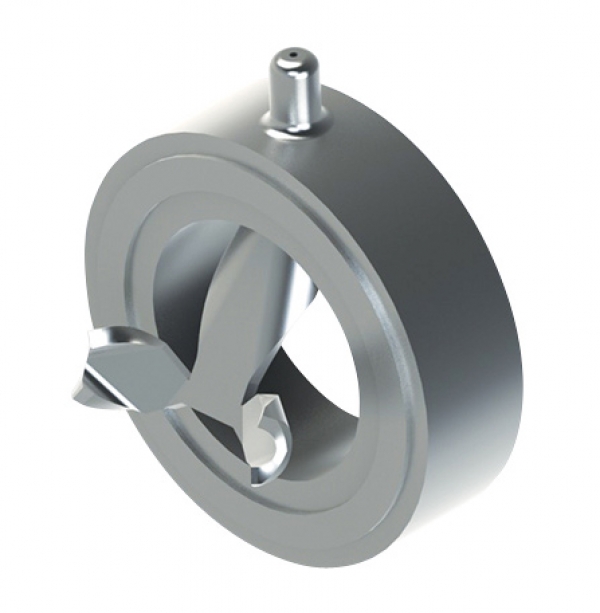

UltraTab

Designed for turbulent flow applications common in water treatment, desalination plants, and chemical processing, the UltraTab delivers a high degree of mixing in a compact space.

Principle of Operation

Turbulent eddies produced from the single mixing element produce mixing of the bulk flow. Injector(s) are provided for additives to the main flow and are introduced to the upstream edge of the element. The additives are quickly dispersed by the element for rapid blending and homogeneity of the fluid.

Mixing Performance

Independent studies from the British Hydraulic Research Group (BHR) shows the UltraTab produces a COv of 0.05 in distances as short as 2D downstream from the mixer. The pressure drop through the mixer is low, providing energy efficiency to the process. An optional extension to the element provides lower COv values, also in as short as 2D downstream from the mixer for complex mixing applications.

Applications

Typical applications include pH control, chlorination, chemical dosing/flash mixing, disinfection, and polymer blending in water treatment applications. Additional applications include turbulent flow mixers in desalination processes, turbulent flow mixers in Chemical Processing, and any all low viscosity blending. The UltraTab is available in a variety of sizes and materials to meet requirements of the piping and process.

Contact our Process Equipment Team:

Michael Bradley (External) – Mob: 086 047 6178

Internal Team

Ken Killoughy – Tel: 021 461 7210

Ross O’Donovan – Tel: 021 461 7230

Vicki McGrath – Tel: 021 461 7207

Tel: 021 461 7200