Diaphragm Pump

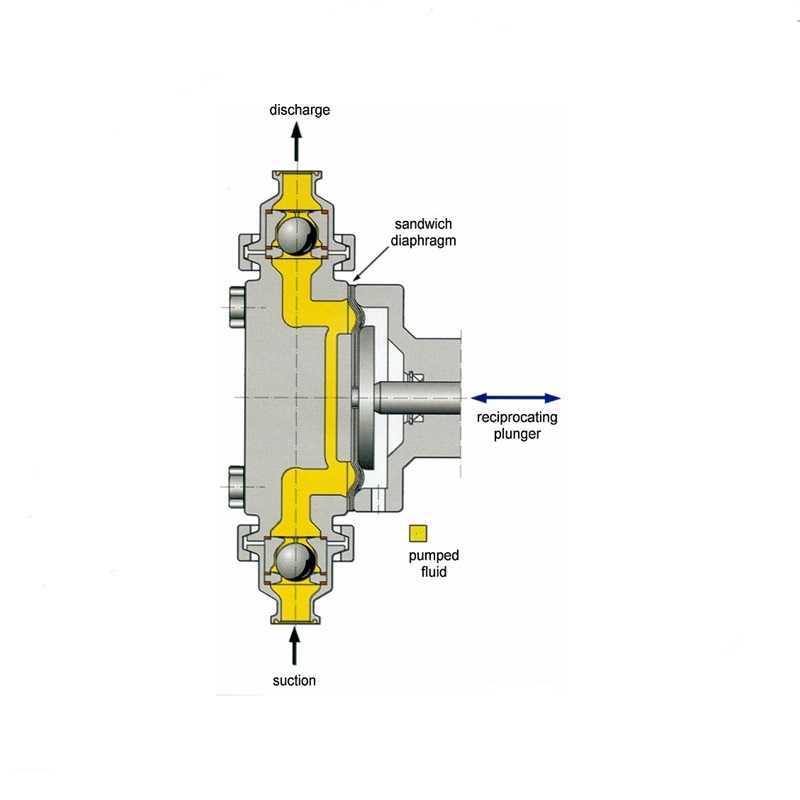

A diaphragm pump is a type of a positive displacement pump that uses a combination of the reciprocating action of a rubber or teflon diaphragm and suitable non-return check valves to pump a liquid.

Sometimes this type of pump is also called a membrane pump.

A double diaphragm pump or an Air Operated Diaphragm Pump (AODD) uses compressed air as a power source. It operates by forcing the air out of one chamber and into the next, this action is simultaneous and results in pumping the liquid out of one chamber and into the discharge piping while the other chamber is filling with liquid.

The main characteristics of a Diaphragm Pump are;

-Low to moderate capacity

-Low to moderate pressure

-Very low efficiencies

-No seal

-High pulsation

Flotronic Pumps’ ‘H’ Series Air Operated Diaphragm pump is ideal for processes where hygiene is a priority.

This AODD pump range has been designed to meet the exacting hygiene standards of 3-A Sanitary Standards, Inc (3-A SSI) and to be used in processes where hygiene is paramount. The ‘H’ Series therefore offers tremendous benefits for the food, beverage and pharmaceutical industries and any other environment where sanitary integrity is necessary.

Cleaning couldn’t be easier

This Air Operated Diaphragm pump range has been designed to meet the high ‘cleanability’ standards demanded by 3-A SSI. These include ease of cleaning for all product-contact and non-product contact parts.

All ‘H’ Series pumps can be thoroughly Cleaned in Place (CIP). The 7” and 10” ‘H’ Series pumps have a support stand allowing rotation of the pump for easy and effective media draining. Gravity separates the ball valves from their seats in this inverted position and cleaning and other fluids easily drain away from the inverted delivery nozzle.

The 12” ‘H’ Series pump has been engineered to drain any CIP solutions while being fully upright – allowing hard piping if required. This larger pump has check ball valve seats engineered to allow drainage without inversion.

All three pumps can be cleaned by flushing with a suitable CIP fluid dependent upon the application and compatibility with the pump wetted component materials. They also have internal radii surface finishes and plastic parts provenance that meet 3-A SSI standards. The innovative, easy-maintenance, ‘ONE-NUT’ design for which Flotronic is renowned is integral to each ‘H’ Series pump – allowing pump maintenance in a matter of minutes.

Reinforced Diaphragm option

Unique to Flotronic, the ‘H’ Series pump can be fitted with diaphragms which are reinforced. Reinforcing plates add support to the diaphragms and ensure that the pumps can withstand CIP/SIP pressures of up to 6 bar in the suction line. This means the pumps can be Cleaned in Place using fully automated CIP units incorporating external CIP pumps, without the need to bypass the pump.

EHEDG accredited versions are also available.

Brochure: Air Operated Diaphragm Pump

Manual: Installation Operation and Maintenance Manual

Contact our Pump Specialist Team:

Phil Soltan (External) – mob: 086 185 3782

Internal Team

Adrian McSweeney – tel: 021 461 7212

Paul-Fox Morris – tel: 021 461 7231

Una Long (Pump & Service Support) – tel: 021 431 7200

Tel: 021 4617 200

Products

-

H Series Sanitary Diaphragm Pumps

View Product -

Minichem PTFE

View Product -

The Good Food Pump – Diaphragm Pumps

View Product -

Slimline Series – Diaphragm Pumps

View Product -

500 Style F Series Polypropylene, PVC, PVDF and aluminium pumps

View Product -

710 Style F Series stainless steel and exotic metal pumps

View Product -

K Style F Series Chemflo virgin and anti-static PTFE pumps

View Product