Standard Cartridge Seal ISC2 Series

The Standard Cartridge Seal ISC2 is a complete family of mechanical seals that provide exceptional reliability and standardization over the widest variety of industrial applications and equipment. ISC2 seals meet all major international standards and are designed for literally hundreds of pump models from global manufacturers. Facilities that standardize with ISC2 seals will immediately benefit from less inventory, greater flexibility, less downtime and longer seal life.

ISC2 seals work hard to eliminate the possible causes of leakage. Our thermal management technology for dry running tolerance, robust seal face drive mechanisms, high-efficiency barrier circulation, rigid setting devices and high-quality materials all contribute to improving seal life even with multiple service conditions, off-design operation, and frequent starts and stops. ISC2 seals are capable of sustaining years of uninterrupted, long-term operation.

Standards:

API682, ASME (ANSI), DIN24960, ISO

The Standard Cartridge Seal ISC2 works hard to eliminate the possible causes of leakage.

- Patented thermal management technology increases dry running and cavitation tolerance.

- A robust drive mechanism for maximum reliability in higher viscosity fluids & frequent stops and starts. Thus preventing breakage of seal faces.

- Optimized high-efficiency barrier circulation promotes cooler running and longer seal life. Double seals include a pumping ring to assist with barrier fluid circulation, cooler running and increased reliability.

- Diamond seal face option for cooler running, abrasive resistance and longer seal life.

- Superior Dry Running capability compared to competitors.

ISC2 seals are capable of sustaining years of uninterrupted, long-term operation. Give us an application and see the results!

Ultrananocrystalline diamond (UNCD ®) coatings offer material properties and performance advancement over all other seal face materials.

Ultrananocrystalline Diamond-Coated Seal Faces

Seal face materials have always been challenged to provide reliable operation in low lubricity fluids. In the past, this challenge was addressed by lubricating seal faces with a cool, clean external fluid. Although effective, this solution adds operating cost throughout the life of the seal. Alternatively, dual seals operating on clean barrier fluid offer longevity with lower operating cost, but higher initial cost for the required support system. The ideal answer for seal users is mechanical seals lubricated directly by the process fluid. UNCD coated silicon carbide as a seal face material enables Flowserve to offer improved reliability in poor lubricating fluids without additional controls.

Features and Benefits of Diamond-Coated Seal Faces

- The lowest friction of any seal face material provides cool running seal faces in poor lubricity fluids such as hot water

- Bonding the hardest known material to the seal face running surface gives maximum resistance to abrasive particle damage

- The highest chemical resistance of all seal face materials enables its use in aggressive acids, alkalines, and caustics

- High wear resistance brings forgiveness for off-design operation such as intermittent dry running

- Fine grain nanocrystalline diamond allows operation against all common mating face materials including carbon, silicon carbide, tungsten carbide, and itself.

- Certification of biocompatibility per USP Class VI is available

Availability of Diamond-Coated Seal Faces

Diamond coated silicon carbide offers performance benefits for a wide range of applications in nearly every industry utilizing mechanical seals. To support this need, diamond coated silicon carbide seal faces are available in most Flowserve pump seals including: – QB series – BX series – ISC2 series – U series – D series – SLC – SLM – SLMP – RIS – HSH

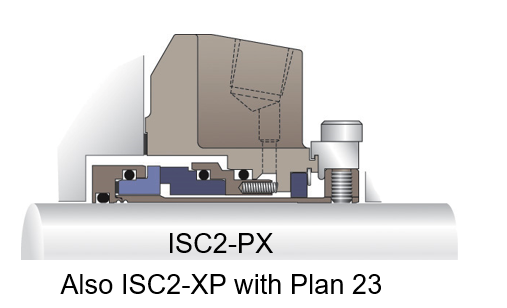

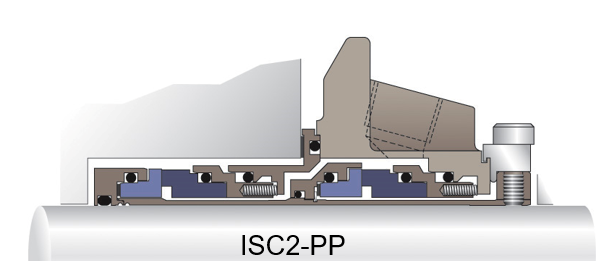

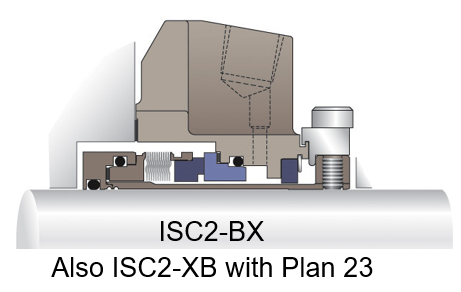

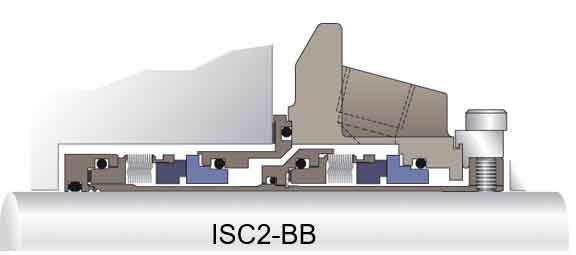

ISC2 seal configurations include:

ISC2 seals are available in a wide range of materials for the best corrosion resistance against aggressive media. Seal chamber specifications from around the world including ASME B-73, EN 12 756, JIS are ISO 3069 fall within the design scope of ISC2 seals. In addition, ISC2-682 seals are fully compliant to API 682 / ISO 21049.

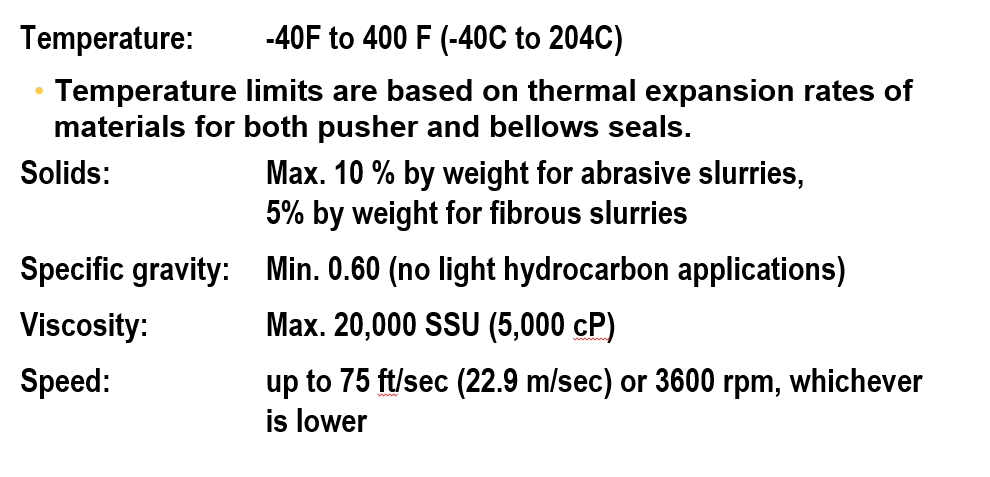

ISC2 Bellows Operating Limits

Applications:

Pipeline, Power Generation, Pulp and Paper, Ag-Chem, Synthetics, Bioprocessing, Tank Farm Transfer, Chemical Processing, Toxic Services, Chemical Transfer, Waste Water, Condensate, Water, Fine Chemicals, General Purpose, Hydrocarbon Processing, Inorganic Chemicals, Light Oils, Light Slurries, Organic Chemicals, Petrochemical Processing

Industries:

Agriculture, Chemical and Liquor, Logistics and Tank Farm, Paper Stock, Pharmaceuticals, Products Pipeline, General Industries

Standard Cartridge Seal ISC2 Series Brochure

Standard Cartridge Seal ISC2 Series BrochureDiamond Coated Silicon Carbide Faces for Seals Brochure

Diamond Coated Silicon Carbide Faces for Seals BrochureContact our Mechanical Seal Team:

Chris Sheeran (External) – Mob: 087 755 9936

Internal Team

Rory Cremin – Tel: 021 461 7213

Tel: 021 461 7200