Mechanical Seal for Pumps

A mechanical seal is the most common type of sealing component used on pumps in modern industry. Replacing out packing over the last 50 or so years, they have served to drastically reduce industry emissions, energy usage and downtime globally.

Types of a mechanical seal for pumps:

A mechanical seal for pumps can be subdivided into variable options depending on the type/specific application/design components/location and mechanical seal characteristics;

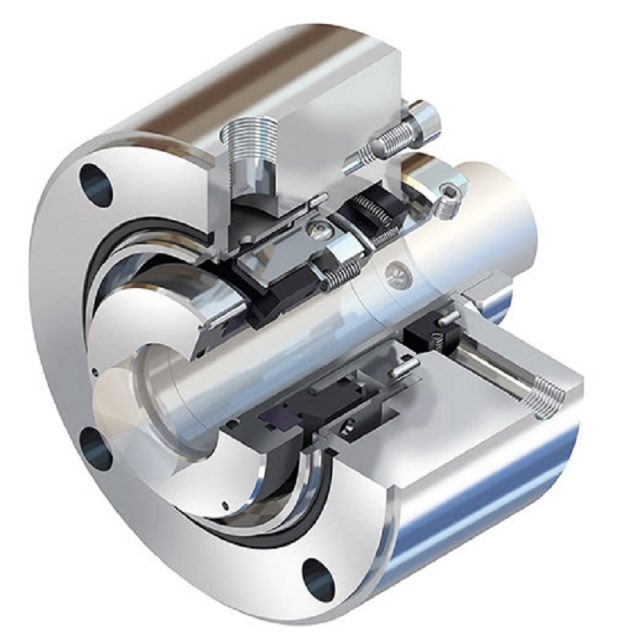

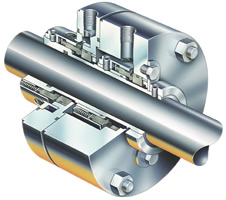

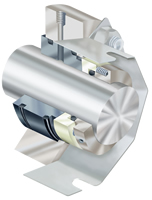

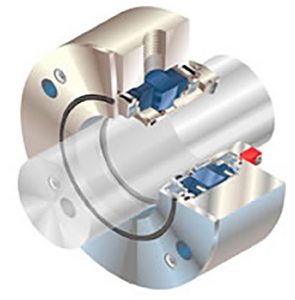

- Component vs Cartridge Seal

A component seal is where the rotating and stationary parts are fitted separately to the machine.

A cartridge seal is preassembled as one part.

The major advantage of a cartridge seal over a component seal is ease of installation. Incorrect installation is a major cause of seal failure, cartridge seals remove many of the problems associated with seal change-out in the field.

- Based on the specific pump application

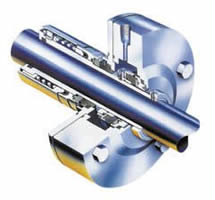

Standard Cartridge Seal – this is a cartridge seal for a standard pump (eg. ANSI B73.1 pump).

Slurry Seal – mechanical seal engineered to cope with a heavy slurry process – i.e. abrasive, corrosive and viscous. Can handle up to 60% slurrys by weight.

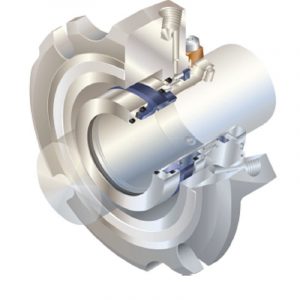

- Based on the design components

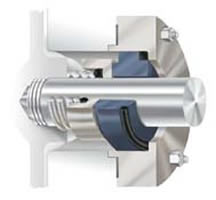

A Pusher Seal is where there is a spring element in the seal (used to maintain contact of the seal faces). Spring types include Belleville, multi-spring, etc. This type of seal requires a dynamic secondary seal.

A Bellows Seal is where the spring element is a bellows. There is no dynamic secondary seal.

- Based on location of the process to the seal faces

ID Pressurised – Where the process is on the inner diameter of the seal face pair.

OD Pressurised – where the process is on the outer diameter of the seal face pair.

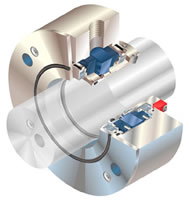

- Based on barrier fluid (double seals only)

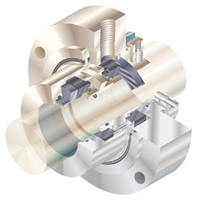

A wet seal is a double seal where the barrier fluid is a liquid.

A gas seal is a double seal where the barrier fluid is a gas – in pumps, this is usually a gas lift-off seal. In a gas lift-off seal the faces are not in contact while the machine is running. They are separated by a thin gas film (flow). If operated correctly they have very low wear.

Single seals on pumps operate using the process fluid as a seal face lubricant.

The above seal types can be combined (though it is not always best to do so i.e. a component gas lift off seal would require very close collaboration between the machine and seal manufacturers to achieve a reliable installation).

There are many other options for mechanical seals, if you have any technical queries on other combinations not listed above, just contact one of our Mechanical Seal Specialists who will gladly discuss your application.

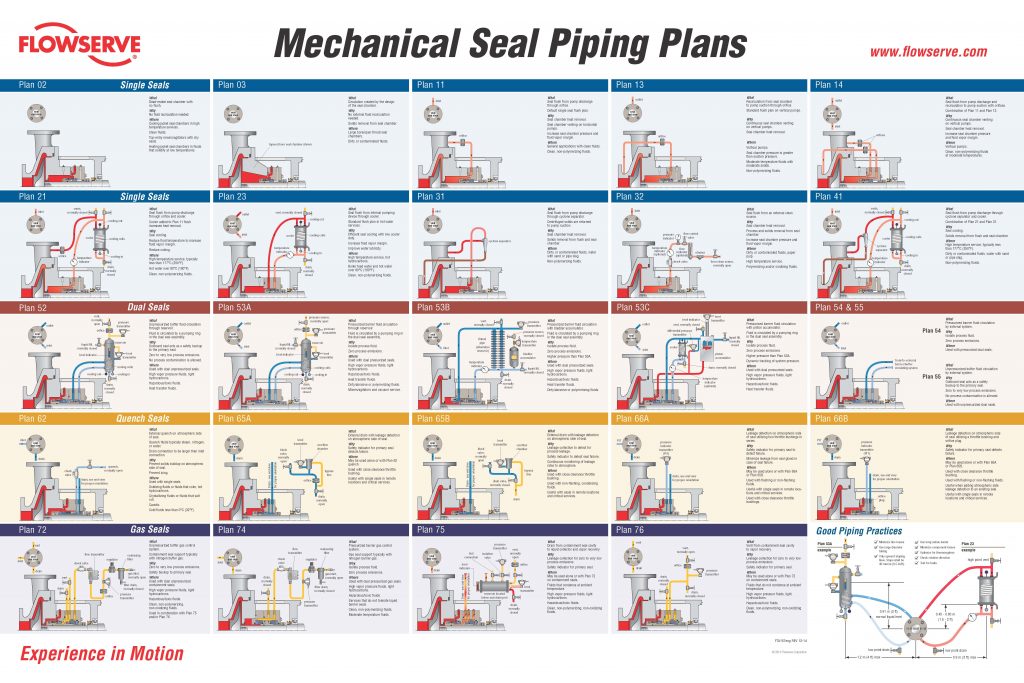

What is a Mechanical Seal Flush in relation to Pumps?

A mechanical seal flush is a piping set-up on a pump and seal assembly where a flow is induced in the seal chamber in order to improve MTBF of the mechanical seal. It is used to improve cooling, heating, remove solids and increase pressure (in combination with a neck or throat bush).

What is a Mechanical Seal Quench?

A mechanical seal quench is a piping set-up where a fluid is piped over the atmospheric side of a seal. It is generally used to prevent precipitation or crystallisation of a product or in some cases to aid cooling.

Technology Solution – A mechanical seal for Pumps:

High Slurry process using Flowserve’s UNCD ® – Ultrananocrystalline diamond seal face technology. Flowserve UNCD ® coatings offer material properties and performance advancement over all other seal face materials.

Slurry seal design expertise applications which previously required double mechanical seals can now be reliably run by using single mechanical seals, saving costs of barrier fluid systems, the costs of the barrier fluid itself & the associated running costs. This reduces energy usage & carbon footprint.

How we can help you?

Flexachem provides a full range of Flowserve Mechanical Seals for Pumps;

- Standard Cartridge Seal – ISC2

- Slurry Seal

- Pusher Seal

- Gas Non Contact Seal

- Bellows Seal

We supply mechanical seals for pumps to the pharmaceutical, bio-pharma, chemical processing, mineral and ore processing and general industries.

If you have a technical query around the installation of mechanical seals for pumps or have some concerns around seal failures, why not contact one of our seal specialists below to discuss it in more detail and find out how we can help solve your issues and get your process running again.

Contact our Mechanical Seal Team:

Chris Sheeran (External) – mob: 087 755 9936

Internal Team

Rory Cremin– Tel: 021 4617213

Tel: 021 461 7200

Products

-

HSH – Pusher Seal

View Product -

GX-200

View Product -

GSD

View Product -

Standard Cartridge Seal ISC2 Series

View Product -

RA / RA-C

View Product -

CRO

View Product -

GSL

View Product -

GF-200

View Product -

ISC2BB

View Product -

CBR

View Product -

Pac-Seal Type 8 and 9 Seals

View Product -

Europac 600

View Product