Progressive Cavity Pump

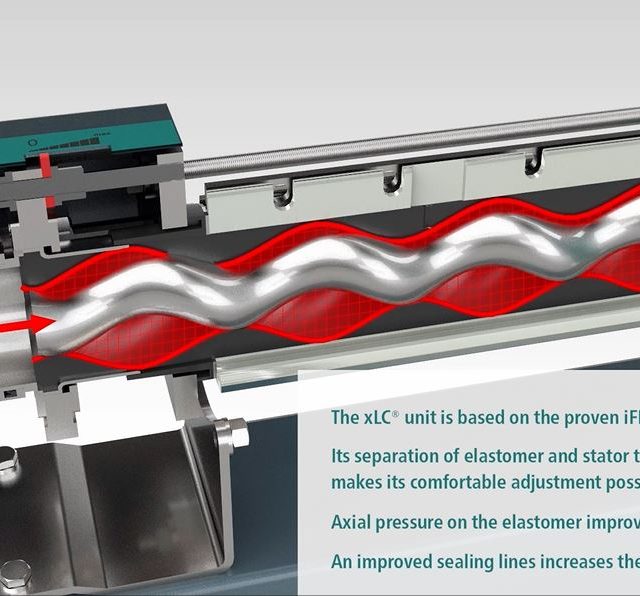

A Progressive Cavity Pump is a type of positive displacement pump which has a rotor rotating within a housing called a stator. The rotor is always metallic and the stator is made up of a rubber type of material. It looks somewhat like a screw thread – the fluid is between the cavities, and the rotary motion of the rotor forces the fluid through from one end to the other.

Progressive Cavity Pumps are used when a product needs to be handled gently and are used in all sectors of industries to convey almost all types of media continuously, and smoothly, with low pulsation, and dosing in proportion to speed. They are used for dosing applications where accuracy is required (multi-stage pumps) their range covers from the smallest dosing pumps with flow rates of a few ml to high-performance pumps that pump up to 1000 m³/h.

One of the main advantages of a progressive cavity pump is that it is easy to regulate the flow of product simply by regulating the pump speed.

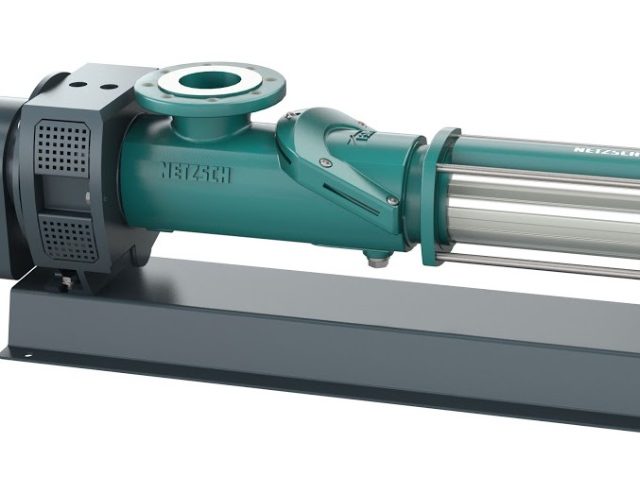

Flexachem are suppliers of the progressive cavity pump for the brand NETZSCH throughout Ireland.

To see for yourself how the Netzsch NEMO® Progressive Cavity pump works – watch the video below.

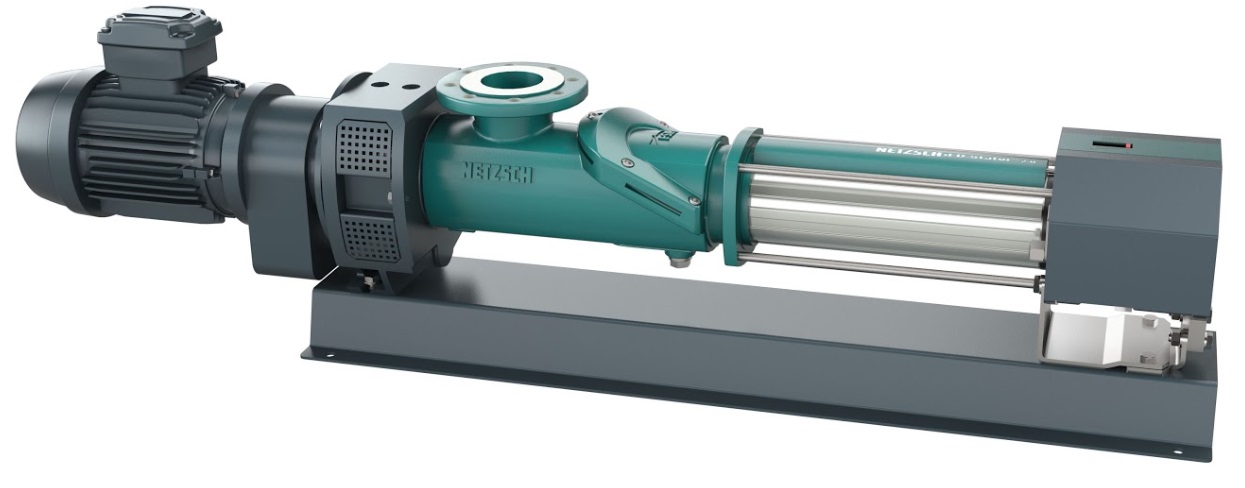

The Netzsch NEMO® Progressing Cavity Pump is also available in Full Service In Place (FSIP®) design …. rotor and stator can be serviced in place without the need of removing the pump from the system.

Contact our Pump Specialists team – if you would like to discuss a particular PC pump application and check out one of our recent articles which we wrote for Engineers Ireland’s website:”How do I choose the correct progressive cavity or rotary lobe pump for my application?“

The Netzsch NEMO® Progressive Cavity block pump is the most widely used progressing cavity pump on the market. Some of its unique characteristics includes;

- Space-saving design and low maintenance costs

- The stator is vulcanised into a metal tube and sealed off by a rubber layer at the two faces of the tube. A flow-in cone is formed at one end of the stator boring. 4 different stator rotor geometries available

- Standard pin joints do not have hardened bushings, but they are sealed and filled with oil for optimum lubrication.

- Standard shaft sealing is fitted with hard metal mechanical seals.

- Compact design with directly flanged drive.

- A versatile modular system meets almost any of our customers numerous requirements.

- The suction flange can be rotated by 4 x 90 ° depending on the installation situation.

- The standard end stud is tapered for standard manometer connection which can also be rotated by 4 x 90 °.

Download Netzsch Nemo Progressive Cavity Pump Brochure

Download Netzsch Nemo Progressive Cavity Pump BrochureContact our Pump Specialist Team:

Phil Soltan (External) – Mob: 086 185 3782

Internal Team

Adrian McSweeney – Tel: 021 461 7212

Paul-Fox Morris – Tel: 021 461 7231

Una Long (Pump & Service Support) – Tel: 021 431 7232

Tel: 021 461 7200