Heat Exchanger

How does a heat exchanger work?

Thermodynamics is the principle of how Heat Exchangers work. The fluid may be enclosed in tubes or plates with a heating or cooling liquid on the outside of the tubes or plates.

The flow rate will affect the amount of heat or cooling that can be achieved, too fast a flow rate and the liquid might not get to get the required output temperature, too low a flow rate and the process media could be damaged, by sticking to the tube wall.

Pressure also changes in a heat exchanger, you will get a pressure drop across the exchanger which depends on the size and flow rate pushed through the exchanger.

The heat exchanger efficiency is defined as the ratio of the heat transferred in the actual heat exchanger to the heat that would be transferred in the ideal heat exchanger.

What are the uses of a heat exchanger?

Heat Exchangers are widely used in many industries, including transportation, energy, oil and gas, the heavy industry, chemical and marine as well as sugar, food and beverage and the HVAC and refrigeration technology sector.

What are the different types of heat exchangers?

There are different types of heat exchangers ranging from;

- Shell & Tube Heat Exchangers

- Plate Heat Exchangers,

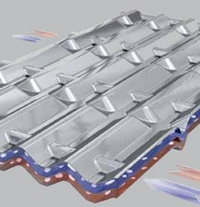

- Compact Fin Heat Exchangers,

- Single Tube Heat Exchangers

- Transformer Cooling Systems.

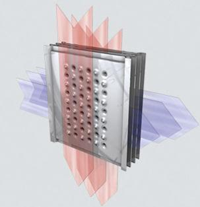

What is a heat exchanger plate?

A heat exchanger plate is a plate type unit which has multiple plates that are joined together in a series, if you want to increase the heat dissipation, you just add more plates, the plates have channels which the liquid passes through.

Plate heat exchangers also differ in the types of plates that are used, and in the configurations of those plates.

What are heat exchangers shell and tube?

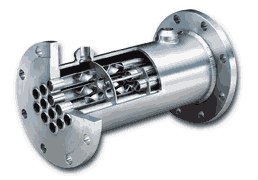

Shell and tube heat exchangers consist of a series of tubes which are fitted in the shell ends, just like the Kenics Unit, the Kenics Units have the addition of mixing elements in the tubes to ensure that higher viscosity liquids are continually turned into the tubes so that it is not just the liquid in contact with the tube walls that is heated or cooled.

Shell and tube heat exchangers are typically used for high-pressure applications as they are robust due to their shape.

What are u tube heat exchangers?

A standard Shell and Tube heat exchanger has straight tubes going to each end of the unit, whereas, a U Tube Unit has the tubes going to only one end of the unit. In other words, the tubes inside the unit are bent into a U and go back to the same end.

Which type of heat exchanger is more efficient? Advantages and disadvantages?

It depends on the application. The Plate type Heat Exchanger is more thermally efficient and cheaper because the sheets are just be stamped out with the channels indented into the Plate and are used in the Dairy Industry for Heating or Cooling Milk, they are only suitable for light liquids and the Plate type Heat Exchanger have a limitation on the pressure rating up to 30 bar.

How do you size a heat exchanger?

You calculate the heat or cooling capacity required to get the required output, the client will inform you of the process temperature and the required temperature to be achieved.

In Kelvion, we use in house selection software to size Plate type heat exchangers.

Which type and brands of heat exchangers does Flexachem supply?

Flexachem supply heat exchangers which offer the highest available coefficients for fast, uniform heat transfer such as; Kenics Shell & Tube with Mixing Elements and Kelvion Plate type Heat Exchangers.

Kenics Shell & Tube with Mixing Elements are custom-built in accordance with our customer’s specifications. We can provide units designed to ASME code and TEMA requirements using state of the design tools for both engineering design and manufacturing.

If you have a particular application concerning a particular Heat Exchanger, why not contact one of our process specialists to find out how our range can help your process.

Contact our Process Equipment Team:

Michael Bradley (External) – Mob: 086 047 6178

Internal Team

Ken Killoughy – Tel: 021 461 7210

Ross O’Donovan – Tel: 021 461 7230

Vicki McGrath – Tel: 021 461 7207

Tel: 021 461 7200