Static Mixer

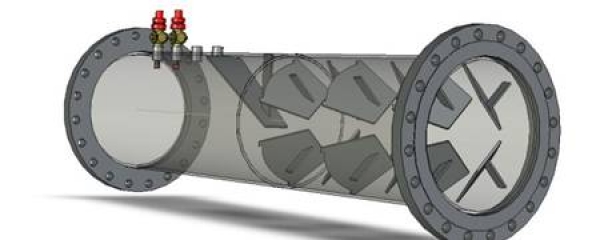

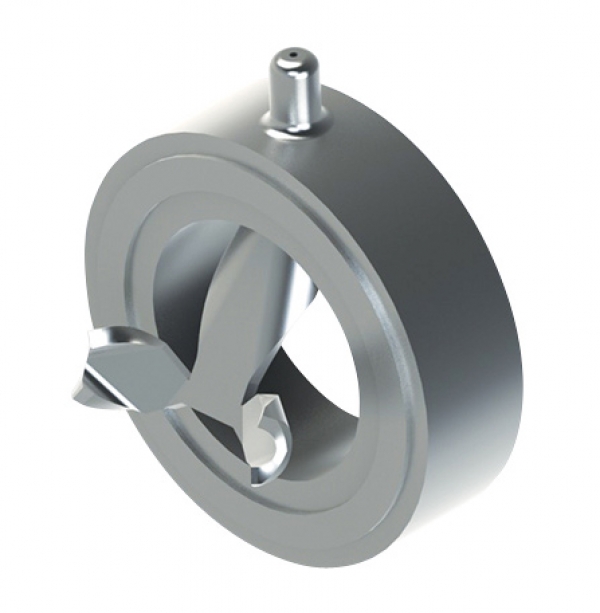

A static mixer is made up of a housing (pipe) and mixing elements or tabs but it has no moving parts, the flow through the mixer will mix the product. Static mixers can be used for liquid, liquid mixing or gas dispersion into a liquid.

Static Mixers are not used for Mixing Powders or Solids into Liquids because the mixing element obstructs the flow and a powder or solid could build up on the mixing elements and block the mixer.

How does a static mixer work?

The mixing element or tabs causes turbulence in the mixer housing which will mix chemicals added either prior to the mixer or through an injection port on the housing of the Mixer. The process media will be 95% mixed within 3D (pipe diameters) of the mixer exit, this is called CoV or Coefficient of Variation.

The target CoV for Static Mixers is a CoV of 0.5 or 95% Mixed at 3D (Pipe Diameters) from the mixer exit.

There is no typical Static Mixer design, there are various designs available to meet the specific applicationl

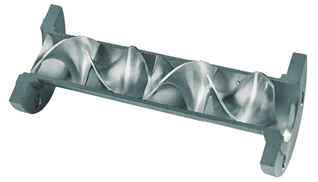

- Helical Coil mixers for the Chemical Pharmaceutical and Food Industries,

- Tab Mixers for the Water Industry – Tab Mixers like the Kenics HEV, WVM and UTS Mixers have the mixing elements (Tabs) mounted on the wall of the mixer housing and are whats called an open design which means that they are less likely to block, they have a lower pressure drop than Helical Coil Mixers.

What is the difference between a static mixer and a static inline mixer?

They are the same, a Static Mixer is inserted into the pipe line and is referred to as a static inline mixer.

How do you size and select a Static Mixer?

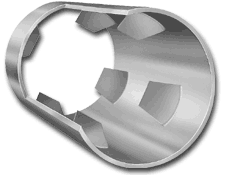

What are helical static mixer elements?

The Kenics KMR & KMS & KME Mixers have Helical Coil Mixing Element which can also be called the Mixing Element Chain.

What is a static mixer heat exchanger?

The Kenics Heat Exchanger has helical mixingelements in the tubes and is used for cooling or heating viscous products, like Bubble Gum.

What is a “static mixer with injection port” used for?

A Static Mixer with an Injection port is used for the addition of a chemical into the main flow through the mixer, the Injection Port is called the side flow.

What are plastic static mixers used for?

Plastic or PVC Mixers are used in the Water Industry and in General industry but can only tolerate Low Temperatures, they operate the same as the metal Static Mixers, PTFE Mixers can be used in the Chemical or Pharmaceutical applications for corrosive Chemical Additions at up to 200°C approx..

How popular are stainless steel static mixers?

Stainless Steel Static Mixers are used in the Chemical and Pharmaceutical Industries where the material is compatible with the process, they are also used in the Water Industry but again only where the process media is compatible with Stainless Steel, in the main, Coated Static Mixers are used in the Water Industry because they are compatible with almost all chemicals and acids, the coating used is made from Plant based materials and is approved by the UK DWI for use in Drinking Water (Potable Water) applications, the Coatings are Rilsan and Scotchcoat and are applied by Electrostatic means in a powder bed, the Mixer Housing with Element is dipped into the Powder Bed and the Coating is Electrostatically applied.

Static Mixer Installation – how do you install it?

Static Mixers can be Flanged to fit into a Pipe System, they can also come with plain ends and the customer supplies the end fittings, they can also come with Tri-Clamp Ends for the Pharmaceutical and Food Industries, the Tri-Clamp End Connections mean that they can be easily removed for the Pipe Line for Cleaning, you do not have to remove bolted Flanges.

Which type of Static Mixers does Flexachem provide?

Flexachem supply the Kenics Range of Static Mixers, models include; the KMR, KMS, UTS, HEV, WVMA.

Almost all our Static Mixers are used in the Water Industry, Chemical/Pharmaceuticals, General industry and for Food Industry applications.

If you have a particular mixing application in mind and wish to discuss our full range of static mixers, why not contact one of our Process Equipment Specialists?

Brochures:

Kensics Static Mixer Technology

Contact our Process Equipment Team:

Michael Bradley (External) – Mob: 086 047 6178

Internal Team

Ken Killoughy – Tel: 021 461 7210

Ross O’Donovan – Tel: 021 461 7230

Vicki McGrath – Tel: 021 461 7207

Tel: 021 461 7200