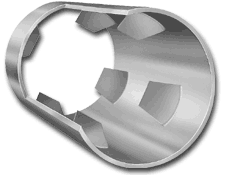

Kenics HEV Mixer

In the HEV Static Mixer, the patented tab geometry maximizes the conversion of turbulent energy into efficient mixing. The HEV produces complete stream uniformity through controlled vortex structures generated by the mixing elements. The element geometry takes advantage of the naturally occurring vortices induced by the element edges. These mixing principles result in an applications technology that can be easily reproduced and reliably scaled. Numerous independent studies have shown Kenics Static Mixers maximize mixing efficiency-without the wasted energy and material blockage typically found in more restrictive motionless mixers

HEV high-efficiency static mixers handle all turbulent-flow mixing applications regardless of line size or shape. Mixing is accomplished by controlled vortex structures generated by the patented low-profile tab geometry. This provides uniform blending while limiting mixer length to less than 1-1/2 pipe diameters. Complete mixing is achieved with pressure losses 75% less than conventional static mixers. Typical applications for the HEV include all low-viscosity liquid-liquid blending processes, as well as gas-gas mixing. The HEV is ideal for processes where pressure loss and length are critical.

HEV Static Mixer features include:

- Lowest pressure drop available

- Unlimited sizes and shapes

- Shortest possible mixer length

- Easy retrofit to existing lines

- Available in all metals and alloys,

FRP, PVC, PFA, and epoxy-coated

steel

HEV static mixers provide installation flexibility and can be configured to square, rectangular or 3-sided ducts. They are adaptable to open channels typically found in water treatment systems.

Product offering

- Sizes: 2″ to unlimited

- Material: Carbon steel, 304, 316, Alloy 20, Monel 400, Hastelloy C-276 & B2/3, Titanium, Nickel 200, Inconnel 600/625, PTFE, PVC, CPVC, FRP and other materials to meet your requirements.

- Geometry: Round, square, rectangular and open-channel geometries

- Retention types: Welded

HEV Static Mixer PDF

HEV Static Mixer PDFContact our Process Equipment Team:

Michael Bradley (External) – Mob: 086 047 6178

Internal Team

Ken Killoughy – Tel: 021 461 7210

Ross O’Donovan – Tel: 021 461 7230

Vicki McGrath – Tel: 021 461 7207

Tel: 021 461 7200