Free Flow Plate Heat Exchangers

Kelvions Free Flow plate heat exchangers are ideally suited for media containing solids and pulp. With their low investment and operating costs these are a viable alternative to shell-and-tube and spiral heat exchangers.

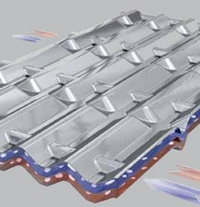

The capabilities of conventional plate heat exchangers are often not sufficient particularly for media containing solids and pulp. These solids tend to clog plate heat exchangers, thus causing costly downtime, such as can occur in bio-ethanol production, in the pulp and paper industry and in waste-water treatment. The NW Series offers a solution to this problem, as thanks to the deeply corrugated plate gap, blockages are practically impossible. The herringbone corrugation with metallic support points ensures the required highly turbulent flow that prevents fouling and contributes to the self-cleaning of the plates and in addition increases the heat transfer performance. Taken in combination, this leads to a longer service life of the plate heat exchanger and your maintenance costs are notably reduced. The gap between the plates can be up to 12 mm

Advantages at a glance

- free flow for media containing particles longer service life.

- lower operating costs minimal pressure loss.

- even with viscous media turbulence promotes the self-cleaning effect high pressure resistance.

Contact Michael on 086 0476178 or Email michael.bradley@flexachem.com

IOM

IOMManufacturing Cert

Manufacturing CertContact our Process Equipment Team:

Michael Bradley (External) – Mob: 086 047 6178

Internal Team

Ken Killoughy – Tel: 021 461 7210

Ross O’Donovan – Tel: 021 461 7230

Vicki McGrath – Tel: 021 461 7207

Tel: 021 461 7200