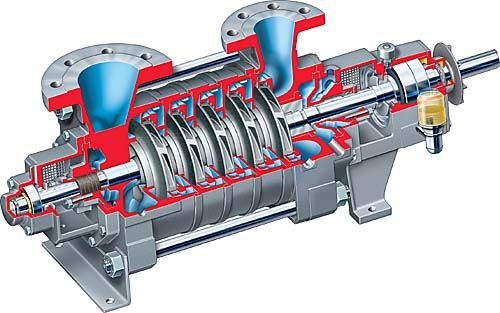

WD, WDX Pump Between Bearing, Radially Split, Multistage

The WD and WDX Pump are radially split, high pressure, multistage, ring section pumps designed for a wide range of process and industrial applications.

Radially Split Casing consists of four separate castings: the discharge head, the suction head, the insterstage casings, and the stuffing box extensions. Multivane Diffusers eliminate radial load to assure long bearing life. Balancing Drum equalizes suction and discharge pressures for more reliable sealing and improved seal life. Reliable O-ring Seals prevent interstage leakage. Each seal is snugly compressed in its own machined groove. Convertible Stuffing Box comes standard with lantern ring. Split packing gland is available for simpler maintenance. Closed Impellers are precision cast and dynamically balanced. Bearing Housings include a labyrinth-type seal backed up with a V-ring for double bearing protection.

- 360° machine registered bearign housing fits

Options

° Multiple flange orientations

° Inducer

° End suction design with product lubricated sleeve bearing

° Radial suction design with product lubricated sleeve bearing

Operating parameters

° Flows to 190 m3/h (800 gpm)

° Heads to 700 m (2300 ft)

° Pressures to 75 bar (1090 psi)

° Temperatures to 210°C (410°F)

Applications:

Utility,General Processing Industry,Pulp and Paper

Features:

- Angular contact, double row thrust bearings

- Unconstrained deep-groove ball bearing design

- 360° machine registered bearign housing fits

WD, WDX Pump Bulletin

WD, WDX Pump BulletinContact our Pump Specialist Team:

Phil Soltan (External) – Mob: 086 185 3782

Internal Team

Adrian McSweeney – Tel: 021 461 7212

Paul-Fox Morris – Tel: 021 461 7231

Una Long (Pump & Service Support) – Tel: 021 431 7232

Tel: 021 461 7200