Rotary Lobe Pump – Sanitary

The Inoxpa SLR Rotary Lobe Pump is a positive displacement pump of a sanitary design suitable for use in the dairies, food-processing, beverage, cosmetics, pharmaceutical and fine chemicals industries. This rotary lobe pump is perfect for managing all kinds of fluid, of either low or high viscosity, as well as for filtering and bottling applications. Products containing fragile solids can be pumped without damage thanks to the specially designed lobes.

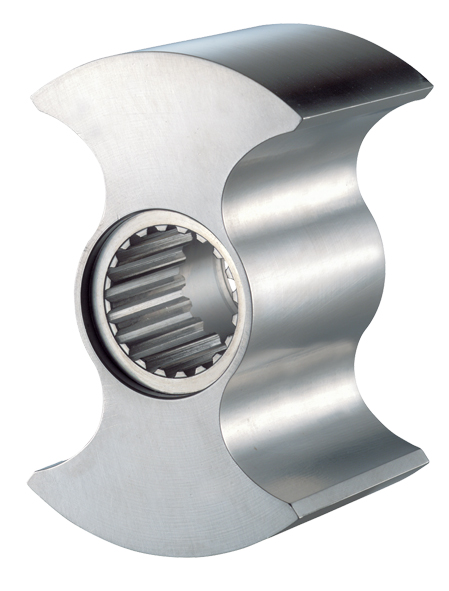

The Inoxpa SLR rotary lobe pump basically consists of two lobe rotors which rotate synchronously inside a casing without touching each other. As the rotors rotate, the spaces between the lobes and the casing are successively filled with the product, which is transported to the discharge nozzle with a fixed amount of displacement. The pumped fluid forms a continuous stream thanks to the tolerances between the lobes and the pump casing, thus ensuring an efficient pumping.

Features

- Horizontal support.

- Bare-shaft construction.

- Stainless steel casing and lobes.

- Tri-lobe rotors.

- Sanitary design of the attachment of the rotors.

- Sanitary mechanical seals.

- Easy cleaning and maintenance.

- Standard connections: DIN 11851.

Materials

- Parts in contact with the product: AISI 316L

- Bearing support: GG 25

- Gaskets: EPDM according to FDA 177.2600

- Mechanical seal: SiC/C/EPDM

- Internal surface finish: Ra ≤ 0,8 µm

- External surface finish: bright polish

Options

- Mechanical seals: SiC/SiC or TuC/SiC.

- Cooled mechanical seal, pressurised double mechanical seal, lip seal or O-ring seal.

- Gaskets in FPM and PTFE.

- Relief valve on the front cover or external by-pass.

- Bi-wing lobes.

- Heating chamber.

- Isolation can.

- Vertical support.

- Rectangular nozzle.

- Various kinds of drives and protections (gearbox drive with an optional frequency converter, pulley/mechanical drive speed selector).

- Trolley and/or control panel.

- Connections: clamp, SMS, RJT, etc.

- ATEX version available.

Technical specifications:

- Max.flow 160 m³/h 705 US GPM

- Max.differential pressure 12 bar 174 PSI

- Max.working pressure 16 bar 232 PSI

- Max.working temperature -10 ºC – +120 ºC (EPDM) 14 ºF – 248 ºF, +140 ºC (SIP, max. 30 min) 284 ºF

- Max.speed 950 rpm

Download Inoxpa SLR Rotary Lobe Pump Brochure

Download Inoxpa SLR Rotary Lobe Pump BrochureContact our Pump Specialist Team:

Phil Soltan (External) – Mob: 086 185 3782

Internal Team

Adrian McSweeney – Tel: 021 461 7212

Paul-Fox Morris – Tel: 021 461 7231

Una Long (Pump & Service Support) – Tel: 021 431 7232

Tel: 021 461 7200