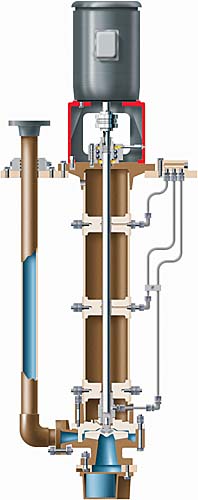

PolyChem VGRP Engineered Polymer Composite Sump Pump

Applications:

Corrosive Services,General Purpose,Water Treatment,Pulp and Paper,Chemical Processing,Utility,Metal and Steel Industry,Pollution Control,Plating

Industries:

Leaching Acid,Chemical and Liquor,Caustic and Chlor-Alkali,Bleach Chemicals,Auxiliary,Acid Transfer,OEM,Water Treatment,Water Supply and Distribution,Wastewater Collection and Treatment,Polymers,Plating, Galvanizing and Other Coatings,Pharmaceuticals,Automotive and Aircraft

Engineered Polymer Composite Construction offers cost-effective corrosion-resistance and is lightweight, non-galling, non-sparking, and non-conductive.

Unitized Case with Integrally Molded Flanges at the suction and discharge nozzles are fully gusseted to ensure structural soundness under extremes of applied nozzle loads.

Externally Adjustable, Semi-Open Impeller is inherently balanced and provides consistently high efficiencies while minimizing maintenance.

Shaft/Bearing System operates well below the first critical speed, resulting in less shaft whip and longer bearing life.

Bearings can be lubricated by external flush, or self-lubricated by the pump fluid.

Single-Piece Column is lightweight, filament-wound, reinforced fiberglass composite but generously sized and thick in cross-section for strength and rigidity.

- Tapered “Polygon” impeller drive

- “Pull-out” bearing retainers

- Choice of shaft metallurgy

- Options

- Operating parameters

- Flows to 565 m3/h (2500 gpm)

- Temperatures from -30°C (-20°F) to 90°C (200°F)

PolyChem VGRP Engineered Polymer Composite Sump Pump Chart

Features:

- Full basket strainer

- NEMA in-line motor

- Fiberglass mounting plate

- Tapered “Polygon” impeller drive

- “Pull-out” bearing retainers

- Level controls

- Choice of shaft metallurgy

316 SS

Alloy 20

Hastelloy

Titanium - 316 SS

- Alloy 20

- Hastelloy

- Titanium

- Options

Simplex and duplex pit covers

Float switches

Particulate seperators

Non-metallic lubrication lines

Tailpipe - Simplex and duplex pit covers

- Float switches

- Particulate seperators

- Non-metallic lubrication lines

- Tailpipe

- Operating parameters

Flows to 565 m3/h (2500 gpm)

Heads to 110 m (350 ft)

Pressures to 17 bar (250 psi)

Temperatures from -30°C (-20°F) to 90°C (200°F) - Flows to 565 m3/h (2500 gpm)

- Heads to 110 m (350 ft)

- Pressures to 17 bar (250 psi)

- Temperatures from -30°C (-20°F) to 90°C (200°F)

Applications:

Corrosive Services,General Purpose,Water Treatment,Pulp and Paper,Chemical Processing,Utility,Metal and Steel Industry,Pollution Control,Plating

Industries:

Leaching Acid,Chemical and Liquor,Caustic and Chlor-Alkali,Bleach Chemicals,Auxiliary,Acid Transfer,OEM,Water Treatment,Water Supply and Distribution,Wastewater Collection and Treatment,Polymers,Plating, Galvanizing and Other Coatings,Pharmaceuticals,Automotive and Aircraft

Contact our Pump Specialist Team:

Phil Soltan (External) – Mob: 086 185 3782

Internal Team

Adrian McSweeney – Tel: 021 461 7212

Paul-Fox Morris – Tel: 021 461 7231

Una Long (Pump & Service Support) – Tel: 021 431 7232

Tel: 021 461 7200