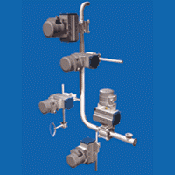

PBM Fabflex Manifold Assembly

Fabflex® Manifold Assemblies are space-savings pipe and valve configurations designed to accommodate special industrial and sanitary applications. Elimination of “dead space” off header with radius pad valves. Gives your the ability to mount multiple valves in a small area to reduce overall envelope. Ability to position valves in almost any position on header

Innovative Solutions

Fabflex valve manifolds are space-saving pipe and valve configurations designed to accommodate special applications in the pharmaceutical, speciality chemical, biotech, semiconductor, cosmetics, and food industries.

Innovative Design

PBM Fabflex Manifold Assembly can be shipped in lengths up to 18′ and in a variety of diameters. They can be equipped with multiple valves, all supplied to match each customer’s configuration. The valves can then be attached to piping or tubing and used as inlets and outlets in the process. To accommodate process expansion, PBM manifolds can also be provided with blank valve pads welded in place for future connections.

Multiple Valve Options

PBM ball valves include industrial, sanitary, steam, or temperature swing options to suit a variety of applications. Manifold valves can be provided as manual or actuated and in an array of materials and sizes. PBM’s valve stems accommodate Direct Mount Actuation for accurate actuator to valve alignment and increased cycle life. This engagement between the stem and the ball is well-suited for high torque applications.

Single Unit Delivery:

PBM delivers each manifold assembly as a single unit. This minimizes the need for individual onsite valve installation and reduces overall installation time.

100% Tested:

Each individual valve, as well as the entire manifold assembly, is completely tested before leaving the factory to ensure adherence to customer specifications and proper performance. This testing reduces the need for time-consuming onsite testing.

Advantages of a PBM Fabflex Manifold Assembly:

- Single, prefabricated assembly reduces field welds and installation time

- Custom built to suit each individual application; can be shipped in lengths up to 12’

- Minimizes dead legs or pocket areas for contamination using cylindrical radius (saddle cut) weld pads

- 100% factory testing of entire assembly reduces the need to test individual valves and components at the job site

- Allows multiple manual or automated valves to be installed in a smaller overall envelope dimension, as opposed to traditional piping methods of tees and elbows

- Shipped as an entire unit to minimize onsite installation and provide greater cost savings over having a contractor complete assembly onsite

- PBM provides layout drawings in digital formats that can be e-mailed directly to the customer for review

- Can be provided with blank valve pads welded in place to accommodate future hookups

- Enables inline valve adjustment when equipped with PBM’s exclusive Adjust-O-Seal® design, which compensates for normal seat wear

- Facilitates easy maintenance and inline replacement of seats and seals when supplied with PBM Series 5 ball valves

PBM Fabflex Manifold Assembly LT-15

PBM Fabflex Manifold Assembly LT-15PBM Sanitary Valves Brochure

PBM Sanitary Valves BrochurePBM Personal Care Brochure

PBM Personal Care BrochureContact our Valve Specialist Team:

Brendan Merrigan (External) – Mob: 087 2598124

Internal Team

Brian Barry – Tel: 021 461 7211

Darragh Rodgers- Tel: 021 461 7241

Miriam Adair- Tel: 021 461 7235

Ross O’Donovan – Tel: 021 461 7230

Shauna O’Connor – Tel: 021 461 7237

Tim Quigley – Tel: 021 461 7209

Vicki McGrath – Tel: 021 461 7207

Tel: 021 461 7200