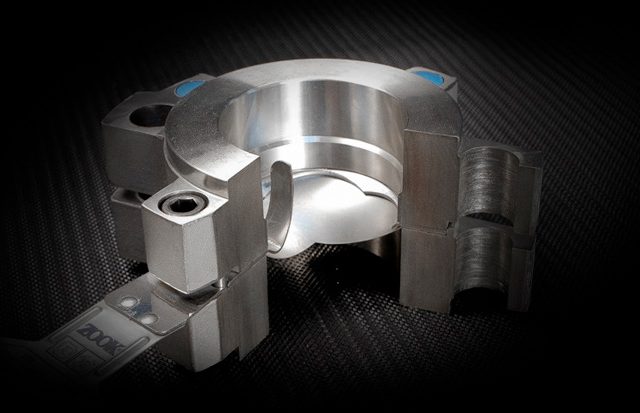

Zook RAH Pre-Torque Bursting Disc Holder

In a continued effort to provide cutting-edge products and technologies for Bursting Disc (rupture disk) users, Zook is pleased to introduce their Zook RAH Pre-Torque Bursting Disc Holder for the RA Series of Bursting Disc (rupture disks). The RA Series offers one unique holder design for use with multiple types of Zook Reverse-Acting metal Bursting Discs (rupture disks). The Zook Pre-Torque Holder Design allows pre-assembly of a Bursting Disc (rupture disk) into a holder prior to field installation.

- Pre-Torque Design:

- One holder design

- Disc dome is contained within inlet holder

- Locating Pin

- Fluoropolymer coated socket head cap screws

- Polyethylene cap screw covers

- Sizes 1” thru 12”

- Holder information is permanently affixed to the O.D. of holder

- Flow direction arrows on disc tag and holder

- Flange class and type-specific

- Positioning hole in mounting lug

- can be used as an extra “hand” when installing into horizontal piping

Options/Accessories for the Zook RAH Pre-Torque Bursting Disc Holder:

Mid/Long Pattern

- Can be machined to meet existing piping specifications

- Prevents Rupture Disc membrane from protruding beyond the outlet holder after burst

Gaskets. Gauge Tap**

- Used for monitoring pressure/temperature at rupture disc location

- Also available on inlet holder

O-Ring Seal

- Teflon encapsulated Viton

Special Coating – Fluoropolymer Teflon Sintered (FS)

- Provides durable, non-stick surface (Requires O-Ring Seal)

Features / Benefits:

- Pre-Torque Design:

pre-assembly of a rupture disc into a holder prior to field installation

removal of the assembly from the piping system for inspection without disturbing the seal integrity of the bursting disc

pre-torque bolts properly seat the disc by engaging the holder bite - pre-assembly of a rupture disc into a holder prior to field installation

- removal of the assembly from the piping system for inspection without disturbing the seal integrity of the bursting disc

- pre-torque bolts properly seat the disc by engaging the holder bite

- One holder design

accepts multiple disc designs (RA4, RA6, RA8, and RAX) - accepts multiple disc designs (RA4, RA6, RA8, and RAX)

- Disc dome is contained within inlet holder

prevents damaging the disc during installation into mating flanges - prevents damaging the disc during installation into mating flanges

- Locating Pin

allows only reverse-acting type discs to be mounted into the holder - allows only reverse-acting type discs to be mounted into the holder

- Fluoropolymer coated socket head cap screws

resists corroding to the holder assembly

provides easy removal without special sockets - resists corroding to the holder assembly

- provides easy removal without special sockets

- Polyethylene cap screw covers

prevents debris from building up in cap screw head - prevents debris from building up in cap screw head

- Sizes 1″ thru 12″

- Standard Holder Materials: Carbon Steel, 316SS, Hastelloy

- Holder information is permanently affixed to the O.D. of holder

- Bubble tight metal-to-metal bite and disc seal

- Flow direction arrows on disc tag and holder

provide permanent visual verification that holder assembly is properly oriented in the piping system - provide permanent visual verification that holder assembly is properly oriented in the piping system

- Flange class and type-specific

guards against installing an assembly into mating flanges with a different pressure rating than the rupture disc holder - guards against installing an assembly into mating flanges with a different pressure rating than the rupture disc holder

- Positioning hole in mounting lug

located in the exact position as the mating flange

allows for proper alignment

can be used as an extra hand when installing into horizontal piping - located in the exact position as the mating flange

- allows for proper alignment

- can be used as an extra hand when installing into horizontal piping

Download Zook RAH Pre-Torque Bursting Disc Holder Spec Sheet

Download Zook RAH Pre-Torque Bursting Disc Holder Spec SheetDownload Zook RAH Holder Spec Sheet

Download Zook RAH Holder Spec Sheet