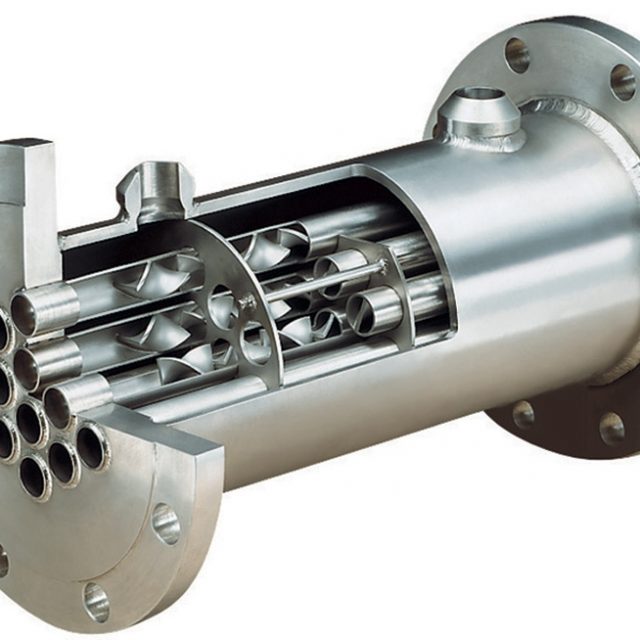

Kenics Shell & Tube Heat Exchanger

Kenics® Static Mixer technology, available exclusively in Kenics® Heat Exchangers, offers the highest available coefficients for fast, uniform heat transfer. Capable of reliable operation in a wide range of process applications, including those in the polymer, plastic, and food and beverage industries, Kenics Heat Exchangers require less space, less energy and less residence time than standard designs.

Static Mixing Technology

The Kenics Heat Exchanger consists of a continuous string of static mixer elements within each heat exchanger tube. Fluid flow is directed radially toward the pipe walls and back to the element, regardless of velocity. Additionally, momentum reversal and flow division also contributes to the mixing efficiency. All processed material is continuously and completely intermixed to eliminate radial gradients in temperature, velocity and material composition. As a result, Kenics Heat Exchangers provide predictable, controlled mixing, and the most efficient form of thermal transfer available today.

Efficient Heat Exchanger Design

By using Kenics Static Mixer elements in each heat exchanger tube, the film build-up commonly associated with laminar flow empty tubes is significantly reduced. Process fluid is continuously pushed from the center of each tube, to the wall and back to the center, eliminating thermal gradients and boosting the inside film coefficient.

Kenics Static Mixer elements produce a more uniform, consistent transfer process, with three to seven times greater heat transfer rates than empty tubes alone. Other characteristics include the following:

- Mixer elements create self-cleaning wiping action

- Plug flow characteristics produce uniform heat history

- Temperature gradients are blended out

- Minimal fouling

- Surface renewal at tube wall reduces chance of thermal degradation

- Viscous materials can cool to near freezing

Kenics Static Mixer elements are furnace brazed to the pipe walls. The resultant enhanced surface area and internal fin effect augment the mixing action to dramatically enhance transfer rates. Removable elements are also available for applications requiring periodic cleaning during product change-overs.

Advanced Design and Fabrication

Kenics Heat Exchangers are custom-built in accordance with our customer’s specifications. We can provide units designed to ASME code and TEMA requirements using state of the design tools for both engineering design and manufacturing. We understand that our heat exchanger units are often critical components in our customer’s processes and that the design and quality is essential. Beyond our expertise in both process and mechanical design, we take great pride in the products built by our experienced and certified welders. Our designs range from low pressure to over 5,000 psi and the design methods have been by over 40 years of installations

Contact our Process Equipment Team:

Michael Bradley (External) – Mob: 086 047 6178

Internal Team

Ken Killoughy – Tel: 021 461 7210

Ross O’Donovan – Tel: 021 461 7230

Vicki McGrath – Tel: 021 461 7207

Tel: 021 461 7200