Check Valve

How does a check valve work?

Check valves are flow sensitive and work to open if the upstream pressure is greater that the seat release presser. The internal seat, spring force or disc allows flow to pass forward, which opens the valve. The seat begins closing the valve as forward flow decreases or is media is reversed, depending on the design.

What are the parts of a check valve?

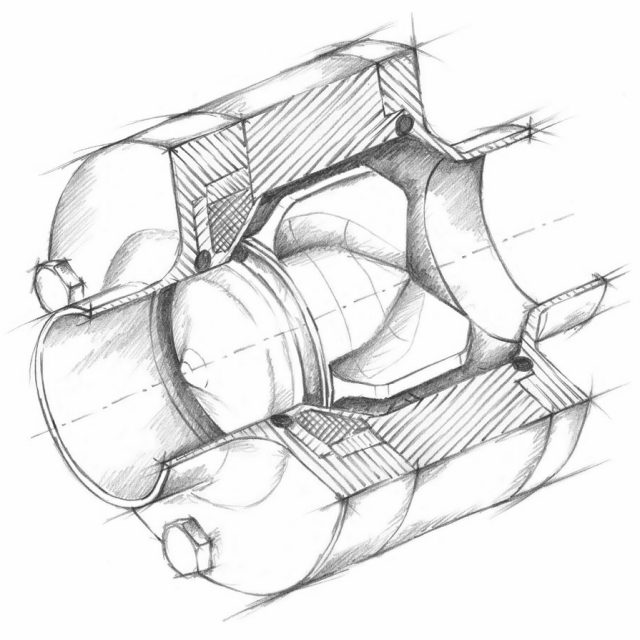

The construction of a check valve is normally simple with only a few components such as the body, seat, disc, and cover. Depending on design, there may be other items such as a stem, hinge pin, disc arm, spring, ball, elastomers, and bearings, and some valves have a very specific opening pressure, and is application dependent.

What are the uses/applications of a check valve?

The main uses of check valves are to prevent back flow of media. Some other applications where they are used in industry are; feed water control systems, dump lines, make-up water, miscellaneous process systems, nitrogen systems, monitoring and sampling systems.

What are the types of check valves?

The most common types of check valves are;

- Swing Type

- Top Hinged

- Tilting disk

- Lift Type

- Piston Type

- Ball type

- Dual Plate Type

- Stop Check Valve

What is the difference between a swing check valves and wafer check valves?

Swing check valves are designed with a disc and hinge mechanism which are then mounted from the top of the valve using a hinge pin. As media passes through the valve, the disk remains parallel with the flow, keeping the valve open. When reverse flow of media occurs, the disc moves back to its rest position, and seal any backflow.

Wafer check valves are very compact in size. The small size of the valve enables it to be set between flanges. The Wafer valve is very common is space saving application. Wafer check valves work in the same principle as Swing, but are a more compact design.

What are the main differences in terms of check valve design between a poppet vs disc vs swing vs piston?

Each of the check valves have their own unique design, but all have similar functions, to allow flow of media in one direction, each valve will be designed into the circuit of piping for a very specific role, these valves will be sized with the correct CV to enable the check valve to function at its optimum level.

What happens when a check valve fails?

When a check valve fails, it can have three possible problem areas,

- Fail open, this is where the flow of media is not controlled and can pass in either direction, resulting in possible back pressure.

- Fail closed, this is where the media cannot pass in the direction of flow, as this is prevented from the seat not opening, or lifting, this will result in pressure build up, upstream.

- Seat damage, if a seal or a seat become damaged, normally due to life cycle of the valve, media, can leak, or pass in both directions of the check valve.

How often should a check valve be replaced?

Check valves like most industrial equipment, have a manufactures life cycle recommendation, depending on various factors, from type of media, pressure, temperature, etc all of these need to be taken into consideration and by carrying out route maintenance, or predictive maintenance, will determine the frequency the valves need replaced.

What are the typical applications for using a Sanitary check valve?

Sanitary check valves would be most commonly used in process to keep a sterile environment where they eliminate area bio-burden and bacteria.

Sanitary check valves would be used in the following applications such as; bio-process media and purified water applications for the bio-pharmaceutical, pharmaceutical, food & beverage and consumer health & beauty industries etc

How can Flexachem help you?

Flexachem have over 38 years plus experience in check valves from alloy check valves, lined check valves and sanitary check valves.

Flexachem can provide actuation for all of our valves, including actuated check valves, our main pneumatic actuator is Norbro, with a variety of switch boxes and feed back control, which is application specific to each installation.

We offer and support leading brands & types of Check Valves;

Flowserve check valves, Ygros, K-Control check valves, Flowserve Atomac lined check valves, PTFE Developments, PBM Sanitary check valves and Ygros Sanitary check valves.

If you would like to find out more about our extensive check valve range, why not contact contact one of our valve specialist team?

Brendan Merrigan (External) – mob: 087 2598124

Internal Team

Vicki McGrath – tel: 021 461 7207

Brian Barry – tel: 021 461 7211

Tim Quigley – tel: 021 461 7209

Shauna O’Connor- tel: 021 461 7237

Ross O’Donovan – tel: 021 461 7230

Tel: 021 461 7200

Products

-

EDF non-return valve

View Product -

EDF non return valve For applications in chemical, pharmaceutical and food

View Product -

Poppet check valves

View Product -

PBM Check Valves

View Product -

Gravity circulation and locks and check valves

View Product -

DISCOCHECK Valves

View Product -

Check Valves RK86 and RK86A

View Product -

DISCOCHECK valves for special applications

View Product -

DISCOCHECK Double Check Valves BB

View Product -

DISCO Swing Check Valves CB

View Product -

Check Valves WB without closing

View Product -

NAF-Check Check Valve

View Product