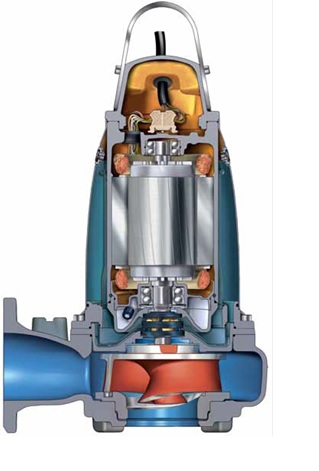

A sump pump is a type of pump which is designed to collect run off liquid or waste at a low point on site as it is possible that in addition to rainwater, if the plant uses chemicals, accidental spills may end up in the sump as well as solid particles of various shapes & sizes whether by accident or design.

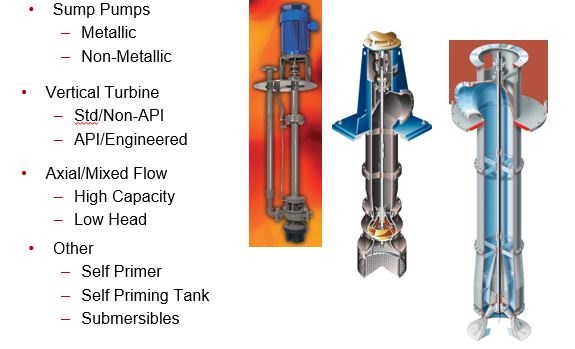

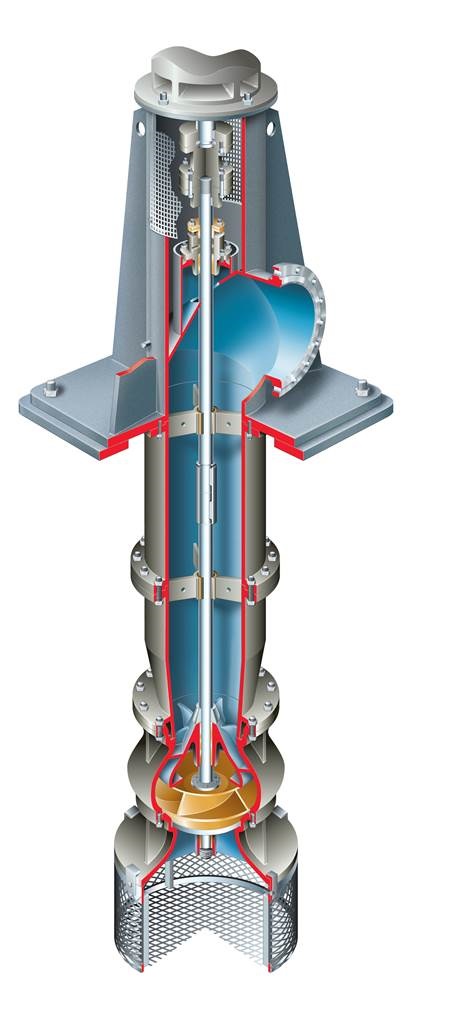

A sump pump can be a family of pumps which can be either immersed or partially immersed in the fluid in the pump i.e submersible pump or a vertical sump pump or a vertical turbine pump. It may also be mounted above the sump at ground level but must therefore be of self-priming design.

Pump types which can be self-priming are centrifugal self-primers, side channel pump, air operated diaphragm pump (AODD) and peristaltic pumps.

Self-priming pumps are inherently designed to allow the pump to re-prime itself typically under lift conditions. These pumps are very effective to the end user in that they will eliminate the need for foot valves, vacuum and ejector pumps which can become clogged or be impractical to use for prolonged or remote operation. Although the pump itself is designed to accomplish this task, it is important to understand the principle of how self-priming is achieved so that the piping system can be designed so as not to conflict with this function.

A self-priming pump, by definition, is a pump which will clear its passages of air if it becomes air bound and resume delivery of the pumpage without outside attention.

How does a sump pump work?

Well it depends on which type of sump pump we are referring to, for example, Submersible, Vertical sump and Vertical turbine pumps do not require priming as the impeller will be submerged in the fluid and the liquid will flow immediately after the pump is turned on.

Other types of sump pumps such as the Centrifugal self-primers, side channel pumps, AODD and peristaltic pumps need to evacuate the air in the suction line before any liquid is delivered. An important consideration is that the displaced air must be vented as some of these pumps are not air compressors! A centrifugal pump usually works on the reflux principle in order to prime.

Air operated diaphragm pump (AODD)

Considerations to be taken into account for the different types of a vertical sump pump.

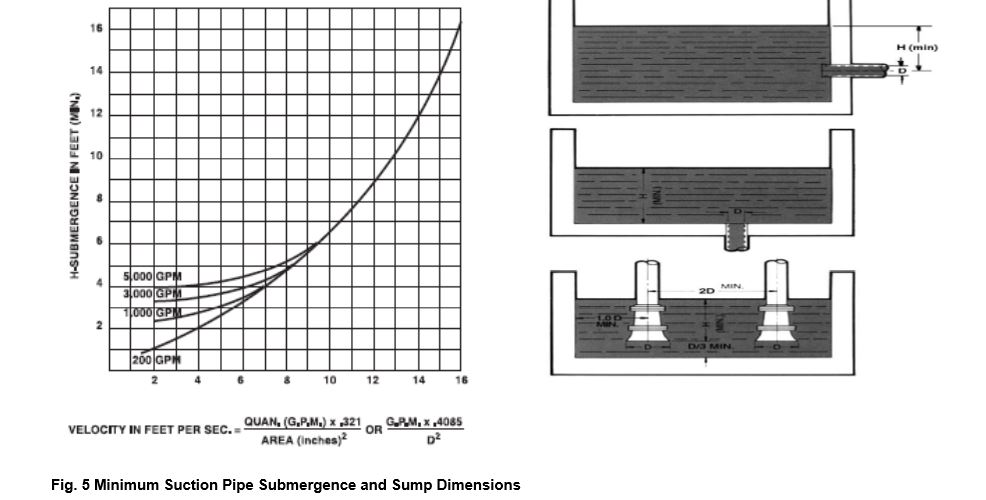

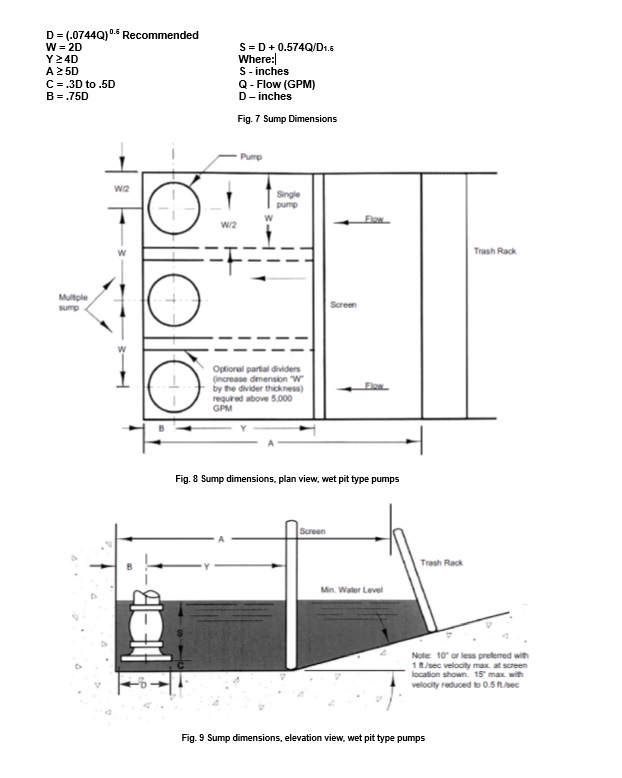

Improper submergence of the pump suction line can cause a vortex, which is a swirling funnel of air from the surface directly into the pump suction pipe. In addition to submergence, the location of the pipe in the sump and the actual dimensions of the sump are also important in preventing vortexing and/or excess turbulence. As little as 5% vortex can cause the pump to operate at an inefficiency of 50%!

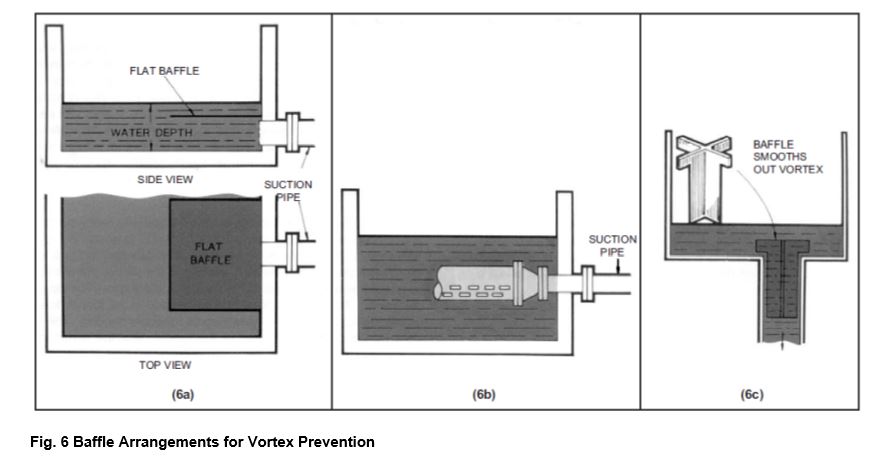

For horizontal pumps, Fig. 5 can be used as a guide for minimum submergence and sump dimensions for flows up to approximately 5000 USGPM (1136 m3/h). Baffles can be used to help prevent vortexing in cases where it is impractical or impossible to maintain the required submergence.

Fig. 6 shows three such baffling arrangements.

On horizontal pumps, a bell should be used on the end of the suction pipe to limit the entrance velocity to 3-8 feet per second. Also, a reducer at the pump suction flange to smoothly accelerate and stabilize the flow into the pump is desirable.

The submergence of the suction pipe must also be carefully considered. The amount of submergence required depends upon the size and capacity of the individual pumps as well as on the sump design. Past experience is the best guide for determining the submergence. The pump manufacturer should be consulted for recommendations in the absence of other reliable data.

For larger units (over 5000 GPM, 1136 m3/h) taking their suction supply for an intake sump (especially vertically submerged pumps), requires special attention.

Why use a sump pump?

As mentioned above a sump is designed to collect run off liquid or waste at a low point on site as it is possible that in addition to rainwater, if the plant uses chemicals, accidental spills may end up in the sump as well as solid particles of various shapes & sizes whether by accident or design. This then must be pumped to a wastewater treatment plant so that the liquid can be neutralised before being pumped into the municipal water system.

It is therefore important that the materials of construction of the pump are compatible with the fluid & that the design of the pump does not become clogged or abraded by solids.

When should you replace a sump pump?

If the pump fails or shows signs of distress, we should ask ourselves, is it suitable for what we are asking of it? Don’t expect the pump to do what it is not designed to do.

There are several factors which may affect its reliability such as.

- Is the material of construction compatible with the fluids and/or solids which maybe present?

- Is it being operated correctly i.e within its POR (preferred operating region)?

- If it’s a self-priming pump, is there adequate NPSH (net positive suction head) i.e is it suffering from cavitation?

- Was the sump designed correctly and in line with the Hydraulics Institute Guidelines?

By preventing the pump to operate outside of the recommended operating range will assure a better reliability factor for the equipment. The old saying of “prevention is better than cure” could help us in the future on spending less time on trouble shooting our pumps.

Need help with a particular sump pump on site? or simply looking for a pump replacement – why not call our pump specialist team.

Contact our Pump Specialist Team:

Phil Soltan (External) – mob: 086 185 3782

Internal Team

Adrian McSweeney – tel: 021 461 7212

Paul-Fox Morris – tel: 021 461 7231

Una Long (Pump & Service Support) – tel: 021 431 7200

Tel: 021 4617 200