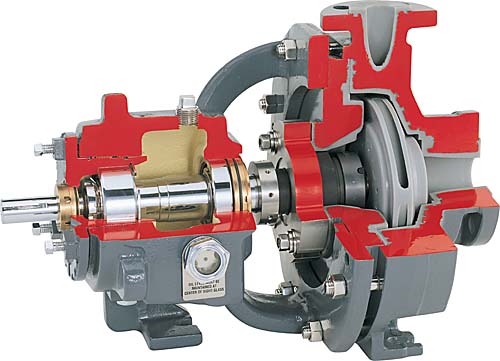

PolyChem S-Series ISO Overhung, Non-Metallic Pump

Applications:

Water Treatment,Corrosive Services,Chemical Processing,Sea Water,Aquariums,Acid Transfer,Brine

Industries:

Pharmaceuticals,Plating, Galvanizing and Other Coatings,Polymers,Water Treatment,Volatile Organic Compounds,Waste Processing,Water Supply and Distribution,Auxiliary,Automotive and Aircraft,Acid Transfer,Solvents,Electronics,OEM,Caustic and Chlor-Alkali

PFA Lined Wet End is globally preferred for its superior corrosion resistance and temperature allowance.

Rugged Metal Armor meets material specifications of GGG40.3.

Separate Inner Magnet and Impeller Components significantly reduces impeller replacement cost compared with integral inner magnet / impeller designs.

Rotating Shaft Design eliminates need for shaft support obstructions in the casing inlet.

Rugged Silicon Carbide Bearings offer the ultimate material for wear resistance and chemical inertness.

- Shaft options

- Bearing housing options

- Operating parameters

- Temperatures from -30°C (-20°F) to 150°C (300°F)

PolyChem S-Series ISO Overhung, Non-Metallic Pump Chart

PolyChem S-Series ISO Overhung, Non-Metallic Pump App

Features:

- Shaft options

Silicon carbide shaft sleeve (standard)

Alloy shaft sleeves

Solid shafts - Silicon carbide shaft sleeve (standard)

- Alloy shaft sleeves

- Solid shafts

- Bearing housing options

Labyrinth oil seals

Magnetic drain plug

Oil slinger

Regreasable or double shielded bearings

Oil mist lubrication - Labyrinth oil seals

- Magnetic drain plug

- Oil slinger

- Regreasable or double shielded bearings

- Oil mist lubrication

- Operating parameters

Pressures to 17 bar (250 psi)

Temperatures from -30°C (-20°F) to 150°C (300°F) - Pressures to 17 bar (250 psi)

- Temperatures from -30°C (-20°F) to 150°C (300°F)

Applications:

Water Treatment,Corrosive Services,Chemical Processing,Sea Water,Aquariums,Acid Transfer,Brine

Industries:

Pharmaceuticals,Plating, Galvanizing and Other Coatings,Polymers,Water Treatment,Volatile Organic Compounds,Waste Processing,Water Supply and Distribution,Auxiliary,Automotive and Aircraft,Acid Transfer,Solvents,Electronics,OEM,Caustic and Chlor-Alkali

Contact our Pump Specialist Team:

Phil Soltan (External) – Mob: 086 185 3782

Internal Team

Adrian McSweeney – Tel: 021 461 7212

Paul-Fox Morris – Tel: 021 461 7231

Una Long (Pump & Service Support) – Tel: 021 431 7232

Tel: 021 461 7200