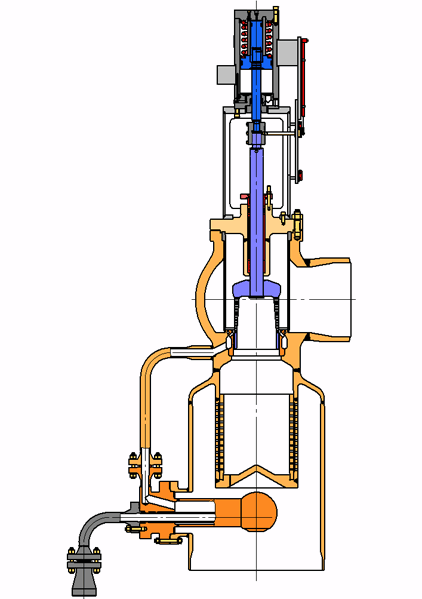

Med/Low Press Steam Cond Valve with Safety Quick cl function DDE

Function

Pressure and temperature control for steam generators and process steam lines/industrial applications

Safety shut-off function for secondary systems

Application

Turbine Bypass with safety function for starting up or stopping steam generators, respectively

Steam transfer in case of turbine failure

Steam conditioning for process steam lines

Design

| Construction: | angular/Z-form |

| Seat-Ø: | 72 – 450mm |

| Capacity: | K-values from 50 m3/h until 4500 m3/h |

| Injection: | secondary atomized steam injection, controlled pressure atomizing |

| Throttling: | controlled/uncontrolled |

| Actuator: | hydraulic or pneumatic |

| Characteristic: | linear/equal percentage |

| Body: | forged, weld connection in accordance with customer specification |

| Leakage rate: | DIN 3230 part 3 – leakage rate 1 as well as ANSI/FCI 70-2 Class V possible |

| Mounting position: | vertical, horizontal and hanging |

| Steam filter: | for SAV-function (3mm hole diameter) |

Contact our Valve Specialist Team:

Brendan Merrigan (External) – Mob: 087 2598124

Internal Team

Brian Barry – Tel: 021 461 7211

Darragh Rodgers- Tel: 021 461 7241

Miriam Adair- Tel: 021 461 7235

Ross O’Donovan – Tel: 021 461 7230

Shauna O’Connor – Tel: 021 461 7237

Tim Quigley – Tel: 021 461 7209

Vicki McGrath – Tel: 021 461 7207

Tel: 021 461 7200