Mechanical Seal for Agitator

Is there a difference between a mechanical seal for agitator and a tank mixer?

No. A tank mixer is another word used to describe an agitator.

Unlike, pumps, a tank mixer is generally not designed to a standard. The exception to this is in Germany where the DIN standards are prevalent on process reactors. Greater pressure fluctuations are prevalent up to pressure reversal situations.

A mechanical seal for agitator is generally in the vapour space of a vessel so external cooling is sometimes required.

What is a Mixer Seal?

A mixer seal is a mechanical seal used specifically on Agitators / Mixers / Vessels.

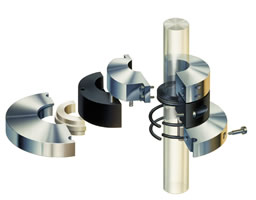

There are top entry, bottom entry and side entry mechanical seals depending on where the agitator is located on the actual vessel.

You can use a mechanical seal in ~99% of agitator applications.

What are the main differences between a Mechanical Seal for an Agitator vs Mechanical Seal for Pumps?

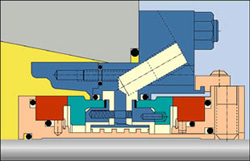

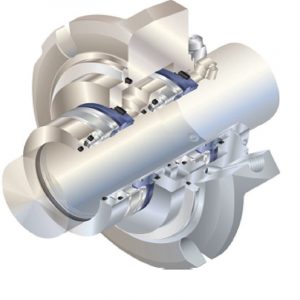

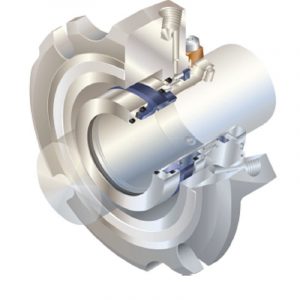

This is best illustrated by the Flowserve standard cartridge seal. This was originally designed as a pump seal. It was then modified to be able to operate as a mixer seal (ISC2-MW). The main difference is that the mixer version is designed to work with increased run-out associated with mixers.

– Shaft sizes are larger for a mechanical seal agitator. There are no widely used standards for agitators / mixers.

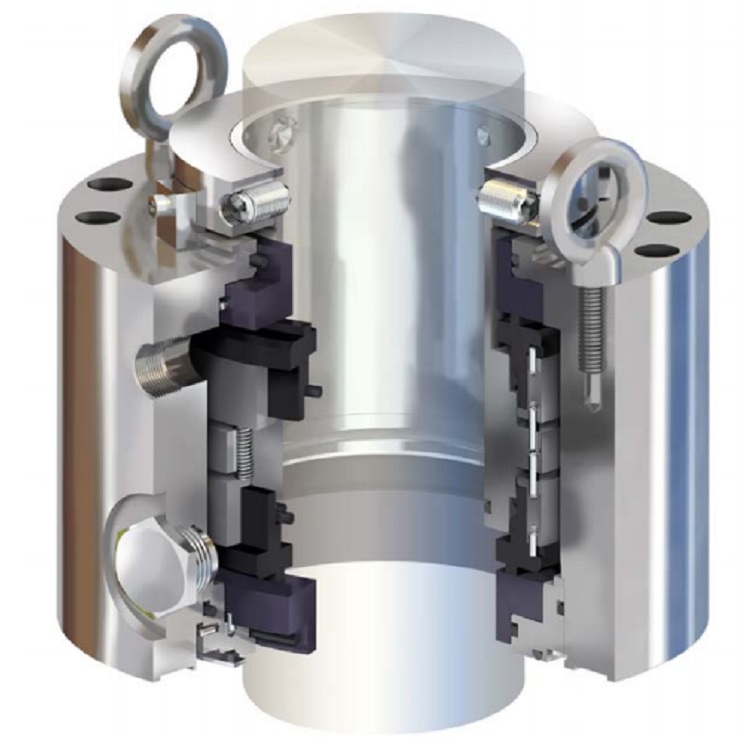

– Mechanical seal for agitator can have a bearing.

– There is increased run out for mechanical seals used on an agitator compared to mechanical seals for pumps.

– There are generally wider ranges of pressure and temperature for a mechanical seal on an Agitator.

– Lower speed agitators than pumps.

– Top Entry Mechanical Seals used on Agitators are in the vapour space of the tank and cooling is different, a cooling flange is sometimes required.

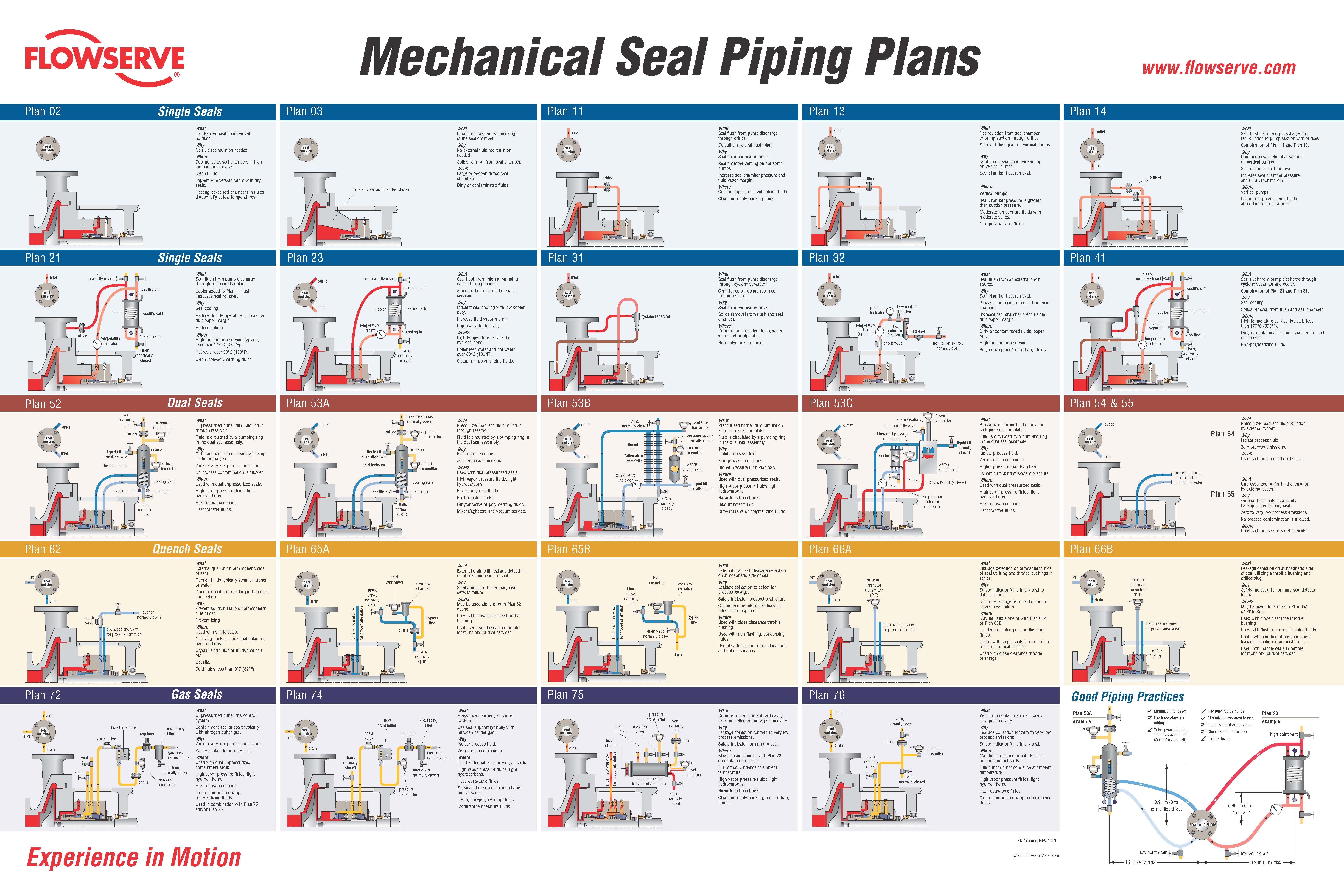

-The piping plans for a Mechanical Seal for Agitators are limited to 53, 54 & 74 plans.

– Cleaning – a mechanical seal for agitator is generally run during CIP (Clean In Place) at low speeds. A mechanical seal can be SIP’d internally for sterilisation.

– Generally, you don’t have a mechanical seal quench on an agitator.

– Due to low speeds and position in the vapour space, single dry-running contacting mechanical seals are available for mixers.

How we can help you?

Flexachem provides a full range of Flowserve Mechanical Seals for Agitator;

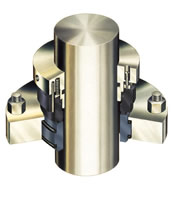

- Double Mechanical Seal

- Single Mechanical Seal

- Slurry Seal

We supply mechanical seals for agitators & tank mixers to the pharmaceutical, bio-pharma, chemical processing, mineral and ore processing and general industries.

If you have a technical query around the installation of mechanical seals for agitators or have some concerns around seal failures, why not contact one of our seal specialists below to discuss it in more detail and find out how we can help solve your issues and get your process running again.

Alternatively, you can diagnose your own mechanical seal failures via our app – just ask us about it!

Contact our Mechanical Seal Team:

Chris Sheeran (External) – mob: 087 755 9936

Internal Team

Rory Cremin – Tel: 021 461 7217

Tel: 021 461 7200

Products

-

SLM 6100

View Product -

SLM 6200

View Product -

Single Seal (VRA)

View Product -

Lift Off and Dry Running (ML-200)

View Product -

Split Seal (MSS)

View Product -

SLC

View Product -

SLM 6000

View Product -

Standard Cartridge Seal ISC2 Series

View Product -

Allpac N

View Product -

Allpac 480/481/487

View Product