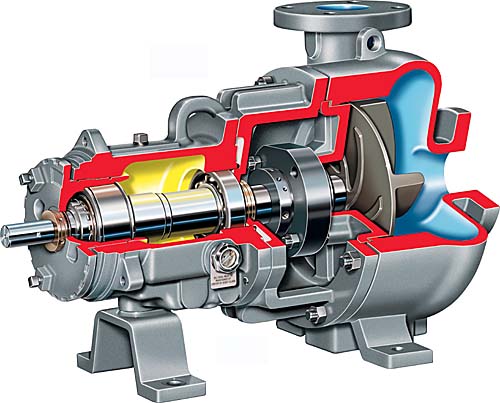

Mark 3 Recessed Impeller Pump

The Durco Mark 3 Recessed Impeller Pump is a Centrifugal Pump type with a recessed design and has a vortex action where only a fraction of the pumped media has physical contact with the impeller resulting in less abrasive wear but still maintaining solids integrity.

Thick-Wall Wet End Components offer extended service life in light slurry, corrosive/erosive services.

Mark 3A Power End with external micrometer impeller adjustment is precisely accurate and enables impeller clearance setting to rear cover in 20 seconds.

ANSI 3A Power End featuring Inpro VBX isolators comes with three-year performance guarantee.

Oversized Shaft and Bearing Components provide extended bearing life and reduced shaft deflection and vibration.

- ANSI 3A Power End

- Inpro/Seal’s VBXX isolators

- Operating parameters

- Flows to 455 m3/h (2000 gpm)

- Temperatures from -75°C (-100°F) to 370°C (700°F)

- ANSI 3A Power End

- Inpro/Seal’s VBXX isolators

- Operating parameters

- Flows to 455 m3/h (2000 gpm)

- Temperatures from -75°C (-100°F) to 370°C (700°F)

Applications:

Large Diameter Solids,General Processing Industry,Acid Transfer,Agriculture,Waste Processing,Chemical Processing,Low Shear Services,Organic Chemicals,Polymers,Solids Handling,Aquariums,Slurries,Chlor-alkali,Solvents,Corrosive Services,Erosive Services,General Purpose,Light Slurries

Industries:

Water Supply and Distribution,Chemical and Liquor,Slurry Processing,Auxiliary,Volatile Organic Compounds,Automotive and Aircraft,Solvents,Acid Transfer,Slurry Transfer,Water Treatment,Waste Processing,Wastewater Collection and Treatment,Primary Processing,Polymers,Pharmaceuticals,OEM,Miscellaneous Services,Electronics,Construction,Caustic and Chlor-Alkali

Features:

- ANSI 3A Power End

Certified clean room assembly

Inpro/Seal’s VBXX isolators

Magnetic drain plug

Synthetic oil bath, oil mist, shielded, grease-lube - Certified clean room assembly

- Inpro/Seal’s VBXX isolators

- Magnetic drain plug

- Synthetic oil bath, oil mist, shielded, grease-lube

- Operating parameters

Flows to 455 m3/h (2000 gpm)

Heads to 120 m (400 ft)

Pressures to 20 bar (285 psi)

Temperatures from -75°C (-100°F) to 370°C (700°F)

Features:

ANSI 3A Power End

Certified clean room assembly

Inpro/Seal’s VBXX isolators

Magnetic drain plug

Synthetic oil bath, oil mist, shielded, grease-lubeOperating parameters

Flows to 455 m3/h (2000 gpm)

Heads to 120 m (400 ft)

Pressures to 20 bar (285 psi)

Temperatures from -75°C (-100°F) to 370°C (700°F) - Flows to 455 m3/h (2000 gpm)

- Heads to 120 m (400 ft)

- Pressures to 20 bar (285 psi)

- Temperatures from -75°C (-100°F) to 370°C (700°F)

- ANSI 3A Power End

Certified clean room assembly

Inpro/Seal’s VBXX isolators

Magnetic drain plug

Synthetic oil bath, oil mist, shielded, grease-lube - Certified clean room assembly

- Inpro/Seal’s VBXX isolators

- Magnetic drain plug

- Synthetic oil bath, oil mist, shielded, grease-lube

- Operating parameters

Flows to 455 m3/h (2000 gpm)

Heads to 120 m (400 ft)

Pressures to 20 bar (285 psi)

Temperatures from -75°C (-100°F) to 370°C (700°F) - Flows to 455 m3/h (2000 gpm)

- Heads to 120 m (400 ft)

- Pressures to 20 bar (285 psi)

- Temperatures from -75°C (-100°F) to 370°C (700°F)

Features:

- ANSI 3A Power End

Certified clean room assembly

Inpro/Seal’s VBXX isolators

Magnetic drain plug

Synthetic oil bath, oil mist, shielded, grease-lube - Certified clean room assembly

- Inpro/Seal’s VBXX isolators

- Magnetic drain plug

- Synthetic oil bath, oil mist, shielded, grease-lube

- Operating parameters

Flows to 455 m3/h (2000 gpm)

Heads to 120 m (400 ft)

Pressures to 20 bar (285 psi)

Temperatures from -75°C (-100°F) to 370°C (700°F) - Flows to 455 m3/h (2000 gpm)

- Heads to 120 m (400 ft)

- Pressures to 20 bar (285 psi)

- Temperatures from -75°C (-100°F) to 370°C (700°F)

Applications:

Large Diameter Solids,General Processing Industry,Acid Transfer,Agriculture,Waste Processing,Chemical Processing,Low Shear Services,Organic Chemicals,Polymers,Solids Handling,Aquariums,Slurries,Chlor-alkali,Solvents,Corrosive Services,Erosive Services,General Purpose,Light Slurries

Industries:

Water Supply and Distribution,Chemical and Liquor,Slurry Processing,Auxiliary,Volatile Organic Compounds,Automotive and Aircraft,Solvents,Acid Transfer,Slurry Transfer,Water Treatment,Waste Processing,Wastewater Collection and Treatment,Primary Processing,Polymers,Pharmaceuticals,OEM,Miscellaneous Services,Electronics,Construction,Caustic and Chlor-Alkali

Durco Mark 3 Recessed Impeller Pump Brochure

Durco Mark 3 Recessed Impeller Pump BrochureContact our Pump Specialist Team:

Phil Soltan (External) – Mob: 086 185 3782

Internal Team

Adrian McSweeney – Tel: 021 461 7212

Paul-Fox Morris – Tel: 021 461 7231

Una Long (Pump & Service Support) – Tel: 021 431 7232

Tel: 021 461 7200