Mark 3 Lo-Flo, ANSI Standard Pump

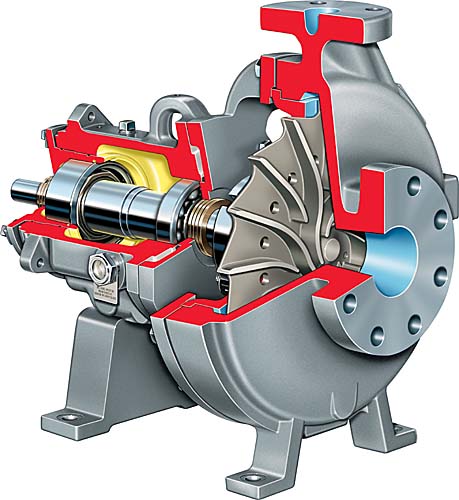

The Mark 3 Lo Flo ANSI Pump is a centrifugal pump type which is reliable in operation at low or throttle flows with a reduction in radial shaft loads due to the special impeller design. It extends the shelf life of Shafts, Bearings & Mechanical Seals.

Circular, Concentric Casing and Radial Vane Impeller reduce radial loads and shaft vibration, extending bearing and mechanical seal life.

Mark 3A Power End with external micrometer impeller adjustment is precisely accurate and enables impeller clearance setting to rear cover in 20 seconds.

ANSI 3A Power End featuring Inpro VBX isolators comes with three-year performance guarantee.

Award-Winning SealSentry Seal Chambers feature unique flow modifiers to extend seal life and improve overall pump reliability.

Oversized Shaft and Bearing Components provide extended bearing life and reduced shaft deflection and vibration.

- Radial vane impeller

- ANSI 3A Power End

- Inpro/Seal’s VBX isolators

- Operating parameters

- Flows to 50 m3/h (220 gpm)

- Temperatures from -75°C (-100°F) to 370°C (700°F)

Applications:

General Purpose,Solvents,Petrochemical Processing,Polymers,Organic Chemicals,Acid Transfer,General Processing Industry,Corrosive Services,Chlor-alkali,Chemical Processing,Aquariums,Hydrocarbon Processing

Industries:

Auxiliary,Automotive and Aircraft,Construction,Electronics,Miscellaneous Services,OEM,Pharmaceuticals,Polymers,Solvents,Slurry Processing,Utilities,Volatile Organic Compounds,Waste Processing,Water Handling and Treatment,Water Treatment,Acid Transfer,Caustic and Chlor-Alkali

Features:

- Offered in a wide range of metallurgy

- Radial vane impeller

Minimal thrust loads

Reduced NPSH requirements

Low seal chamber pressures

Longer seal and bearing life - Minimal thrust loads

- Reduced NPSH requirements

- Low seal chamber pressures

- Longer seal and bearing life

- ANSI 3A Power End

Certified clean rooom assembly

Inpro/Seal’s VBX isolators

Magnetic drain plug

Synthetic oil bath, oil mist, shielded, grease-lube - Certified clean rooom assembly

- Inpro/Seal’s VBX isolators

- Magnetic drain plug

- Synthetic oil bath, oil mist, shielded, grease-lube

- Operating parameters

Flows to 50 m3/h (220 gpm)

Heads to 300 m (1000 ft)

Pressures to 30 bar (450 psi)

Temperatures from -75°C (-100°F) to 370°C (700°F) - Flows to 50 m3/h (220 gpm)

- Heads to 300 m (1000 ft)

- Pressures to 30 bar (450 psi)

- Temperatures from -75°C (-100°F) to 370°C (700°F)

Applications:

General Purpose,Solvents,Petrochemical Processing,Polymers,Organic Chemicals,Acid Transfer,General Processing Industry,Corrosive Services,Chlor-alkali,Chemical Processing,Aquariums,Hydrocarbon Processing

Industries:

Auxiliary,Automotive and Aircraft,Construction,Electronics,Miscellaneous Services,OEM,Pharmaceuticals,Polymers,Solvents,Slurry Processing,Utilities,Volatile Organic Compounds,Waste Processing,Water Handling and Treatment,Water Treatment,Acid Transfer,Caustic and Chlor-Alkali

Durco Mark 3 Lo-Flo Brochure

Durco Mark 3 Lo-Flo BrochureContact our Pump Specialist Team:

Phil Soltan (External) – Mob: 086 185 3782

Internal Team

Adrian McSweeney – Tel: 021 461 7212

Paul-Fox Morris – Tel: 021 461 7231

Una Long (Pump & Service Support) – Tel: 021 431 7232

Tel: 021 461 7200