Low Shear Pump

A Low Shear Pump is a pulsation free pump which produces little or no turbulence through the action of its pump. Low shear in pumping relates to a relative motion between adjacent layers of the fluid. Low shear means that the flow is not turbulent i.e smooth or laminar.

Laminar flow means layered fluid – different layers of fluid move through the pipe in a straight line unlike turbulent flow where the direction of the fluid as it travels is quite random n essence and it mixes together.

By maintaining laminar flow through the pump and in the piping system, it helps to reduce or prevent damaging turbulent flow.

What is the working principle of a low shear pump?

The key working principles behind low shear pumping are;

- low fluid velocity (laminar flow rather than turbulent flow).

- low rotational speed of the pump.

- specific design characteristics of the impeller or rotor (e.g progressive cavity pump).

- For the helical screw impeller pump, the gentle pumping action of this pump type is similar to having an elbow in the piping system, therefore, turbulence is kept to a minimum.

- The recessed impeller or vortex type does have a higher amount of turbulence in the pumping action.

What are examples of shear sensitive liquids?

Some examples of shear sensitive liquids include;

Cream – dairy industry, latex and some paint products & emulsions,

Pharmaceutical slurries containing small crystals, food stuffs, resin, algae, seafood and eggs.

What are the different types of low shear pumps?

There are several “types” of commonly found pumps which may be considered low shear i.e progressive cavity pump, helical screw impeller pump, screw pump, the vortex type Centrifugal pumps – Durco Mark 3 recessed Impeller pump and the disc rotor pump.

Standard maintenance practices can be used on all types of low shear pumps as there is nothing that is radical in terms of design.

What are the uses and applications of a low shear pump?

The main use and applications of a low shear pump is for any fluid that is delicate and the qualities of which may be damaged or destroyed due to turbulent flow. By using low shear pumps, the quality of the finished product may be increased and the waste significantly reduced.

If there are abrasive solids in the fluid and the flow is laminar, the “angle of attack” of the solid on the working parts of the pump is either reduced or eliminated, therefore, the wear of the pump is lower, leading to a longer lifetime.

How can you reduce pump shear in a Sanitary Pump?

For a sanitary pump, in particular a centrifugal pump type, the shearing action may be reduced to a degree by using a pump at lower speeds, however, this may result in a relative poor pump selection.

Take a look at our article written for the Engineers Ireland Journal – pump sizing and selection – can you afford to get this wrong?

What is a disc rotor pump?

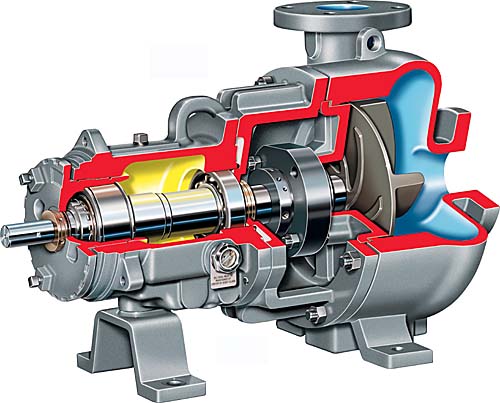

A disc rotor pump is a pump type that outwardly looks identical to a Centrifugal pump but it has a special design of an impeller (otherwise known as Discpac™), these Discpacs can be provided with multiple discs as well as a “high head” and the choice of Discpac™, is largely application dependent.

How does a disc rotor pump work?

The disc rotor pump works using the Discpac™, a series of parallel discs which form the pumping mechanism. As the discs rotate, energy is transferred to successive layers of molecules in the fluid between the discs via the principle of “boundary layer and viscous drag”.

When fluid enters the disc pump, due to laminar flow conditions, streams of liquid travel at different speeds through a pipe with the layer closest to the pipe wall being stationary – known as the Boundary Layer which is formed on the surfaces of the Discpac™ – and successive fluid layers flowing faster toward the centre of the pipe via the Viscous Drag Principle, generating velocity and pressure gradients across the width of the Discpac™.

This combination of boundary layer and viscous drag results in a powerful force that “pulls” the product through the pump in a smooth,pulsation-free flow.

The discflo pump produces no pulsations where in some applications this may be undesirable.

What are the uses and applications of a disc rotor pump?

The main use and application of a disc rotor pump is for any fluid that is delicate and the qualities of which may be damaged or destroyed due to turbulent flow.

Other applications include where there maybe large or small amounts of entrained air or gas (up to 80%) and also in applications where NPSH available would be low or even zero as these pumps require ~ 1/4 NPSH of what a comparably sized centrifugal pump and high viscosity fluids where the centrifugal pump can’t handle efficiently.

Also, solids-laden fluids (more than 80% solids) or where small or very large solids are present i.e. whole chickens or fish.

Even when the Discflo pump is cavitating, damage will be minimal because the gas bubbles which are formed stay between the discs and as they implode, they are not in contact with the pump components which is when damage would normally occur in other pump types.

What are the key features of a disc rotor pump?

The disc rotor pump has a very very low minimum flow and low radial loads which results in longer mechanical seal and bearing life.

Also a mixer is available using the low shear mixing technology.

Which low shear pump manufacturers does Flexachem collaborate with?

Flexachem collaborates with world leading Manufacturers of Low Shear Pumps and supply the following brands and types of pumps;

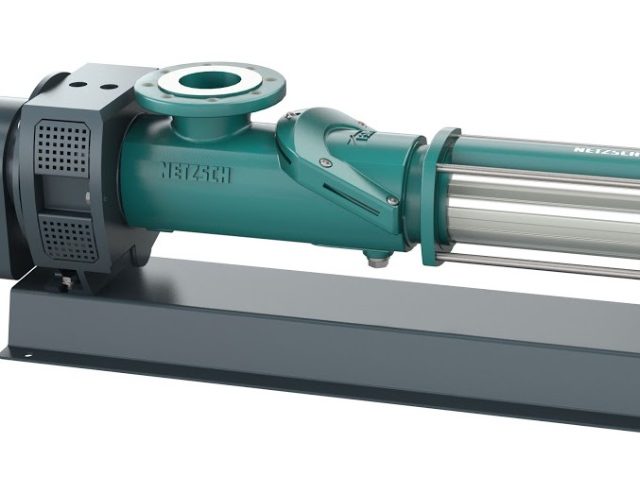

Netzsch – progressive cavity pump and multi screw pump

Inoxpa – RV helical screw impeller pump

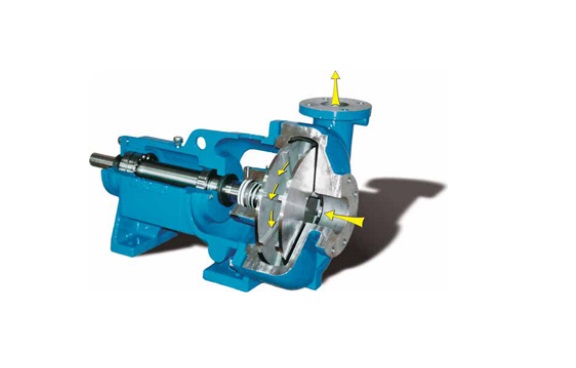

Flowserve Durco – the vortex type Centrifugal pumps –Mark 3 recessed Impeller pump

We also have an extensive inventory of Low Shear Pump and Spare Parts in stock so let us know what you are looking for, and in the off chance that we do not have it in stock, we will source it for you!

We provide localised technical support & on-site service engineering to support your operational needs.

Want to discuss a particular application in more detail – why not call one of our Pump Specialist team.

Contact our Pump Specialist Team:

Phil Soltan (External) – mob: 086 185 3782

Internal Team

Adrian McSweeney – tel: 021 461 7212

Paul-Fox Morris – tel: 021 461 7231

Una Long (Pump & Service Support) – tel: 021 431 7200

Tel: 021 4617 200