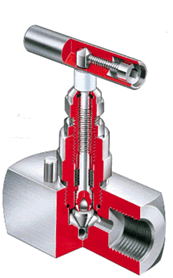

Hand Operated Needle Valves

Features.

- Fully engaged rolled bonnet threads protected from process media by a metal body/bonnet seat.

- Swaged self centring non rotating Duplex stem point ensures positive seat closure under all conditions

- Rolled stem threads protected from process media by fully adjustable “sandwich” packed gland

- Fully backseating – in bonnet with anti-blowout stem Totally encapsulated dust seal gives greater stem head protection.

- Vibration proof handle with positive location and excess torque break feature.

- All pressure wetted parts fully traceable and certified in accordance with EN10204-3.1b

- NACE MR-01-75 Standard.

- All manifolds suitable for use within enclosures.

- Fully developed field mounting system for all products.

- All options available. Full range of materials, thread types and sizes.

- 10,000 PSI C.W.P. option.

- Ball valves option

- Monoflanges and Modular Double Block and Bleed Valves.

Contact our Valve Specialist Team:

Brendan Merrigan (External) – Mob: 087 2598124

Internal Team

Brian Barry – Tel: 021 461 7211

Darragh Rodgers- Tel: 021 461 7241

Miriam Adair- Tel: 021 461 7235

Ross O’Donovan – Tel: 021 461 7230

Shauna O’Connor – Tel: 021 461 7237

Tim Quigley – Tel: 021 461 7209

Vicki McGrath – Tel: 021 461 7207

Tel: 021 461 7200