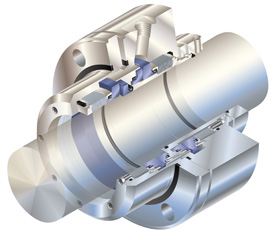

GTSP Seal

Dual pressurized, high temperature metal bellows gas seal

Brands:

Flowserve

Industries:

Alkylation,Catalytic Cracking,Crude Handling and Treatment,Distillation,Heavy Oil and Upgrading,Hydrocraking,Hydrotreating,SAGD

The GTSP is a dual pressurized, high temperature metal bellows gas seal for the hottest process pumps found in refinery and hydrocarbon services.

Utilizing Flowserve’s exclusive bi-directional wavy face topography, the GTSP seal, pressurized with dry steam or nitrogen, is specially engineered to drive exceptional, long-term equipment reliability and lower energy consumption.

Wavy face technology creates a gas film barrier between the seal faces to provide non-contacting, low drag, low energy consumption performance.

Allow 718 welded metal bellows assembly construction offers the highest resistance to stress corrosion cracking in high temperature, sulfuric-laden services.

Applications:

Industries:

Alkylation,Catalytic Cracking,Crude Handling and Treatment,Distillation,Heavy Oil and Upgrading,Hydrocraking,Hydrotreating,SAGD

GTSP Seal Brochure.pdf

GTSP Seal Brochure.pdf