Full Bore Ball Valves – AKH2

Full bore ball valves have an oversized ball so that the hole in the ball is the same size as the pipe internal diameter which ensures straight-through flow and positive shut off with minimal pressure drop and very little resistance to the flow of liquid.

Choosing the correct ball valve for your application can be very important. Full Bore Ball valves are typically used in applications where free flow is required such as pigging in Pipelines.

AKH2 Atomac Lined Ball Valve for all your free-flowing applications

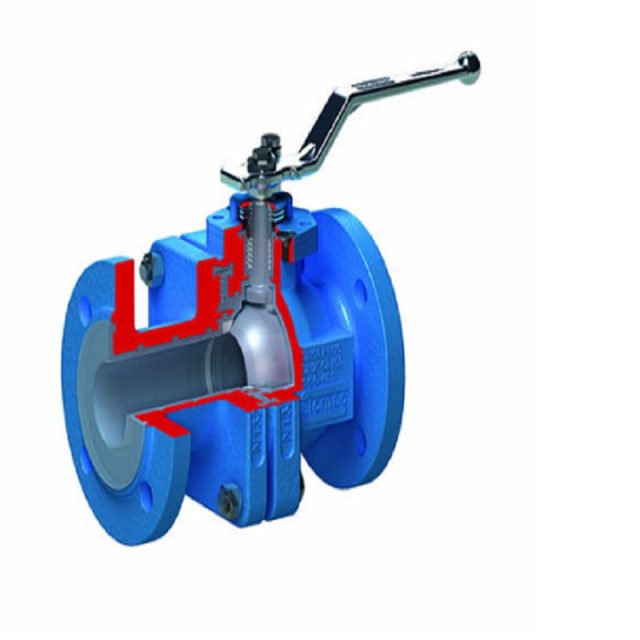

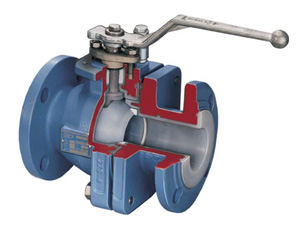

The AKH2 Atomac Lined Ball Valve is a two-piece full bore standard lined ball valve with a corrosion resistant fluoropolymer lining. The full port design minimises pressure loss and increases flow capacity to reduce energy and pumping costs. It features an ISO 5211 universal mounting pad which allows for easy automation even with the valve in the pipeline.

How Flexachem can help you?

Flexachem is the leading distributor for the sizing & design of Ball Valves throughout Ireland. We represent the brand Flowserve Atomac Lined Ball Valves which offer PTFE, PFA and Ceramic lined ball valves and we are the distributor for them throughout Ireland.

We have a dedicated Valve Specialist team who are highly experienced and industry trained who can help you select the shortest possible length from the available sizes in which they can fit the ball, seats, flanges, assembly of the flange and any body bolting. Our Service Engineers provide localised technical support & on-site service engineering to support your operational needs. We also hold a heavily stocked inventory to help take the pressure off you in the event of unexpected emergencies.

We offer a full range of actuated lined ball valves, such as Full Port (Full Bore), Reduced Port (Reduced Bore), Long Pattern, Short Pattern, Tank Outlet Valve/Drain Valve, Divert Valve and Glass Pipework Valve.

The main benefits of using the AKH2 Atomac Lined Ball Valve is that it provides a bubble-tight shut off, low maintenance, no-leak stem seals, the graphite bearing prevents side loading and extends seal life and it has a safety anti blow-out stem design in place.

The Atomac lined ball valves are engineered to include a free-floating ball design which offers additional benefits; low frictional coefficients resulting in low operating torques, Positive shut – off across the pressure range and a reduction of stem side loads eliminating potential leaks to the atmosphere through the valve gland.

The fluoropolymer thick liner material is 100% inspected at 20,000 high voltage for defects and is made from a high corrosion resistant FEP to 300°F (150°C) or PFA to 400°F (200°C). A variety of metallic and non-metallic ball material options are also available.

The material specification of the valve body and ball is Ductile Iron A395, FEP/PFA, DIN EN 1563*

*DIN dimensional only – not available to ANSI (ASME ) dimensions.

1⁄2 in (15 mm) through 12 in (300 mm)

The AKH lined valves are now available with CF-8M stainless steel body armour, ball and stem inserts and have an optional V-port ball for modulating control.

Typical Industries:

Leaching Acid, Pharmaceuticals, Waste Processing, Water Treatment, Food Processing, Agriculture, Bleach Chemicals, Caustic and Chlor-Alkali, Chemical and Liquor, Acid Transfer.

Flowserve Atomac AKH2 Lined Ball Valve Brochure

Flowserve Atomac AKH2 Lined Ball Valve BrochureContact our Valve Specialist Team:

Brendan Merrigan (External) – Mob: 087 2598124

Internal Team

Brian Barry – Tel: 021 461 7211

Darragh Rodgers- Tel: 021 461 7241

Miriam Adair- Tel: 021 461 7235

Ross O’Donovan – Tel: 021 461 7230

Shauna O’Connor – Tel: 021 461 7237

Tim Quigley – Tel: 021 461 7209

Vicki McGrath – Tel: 021 461 7207

Tel: 021 461 7200