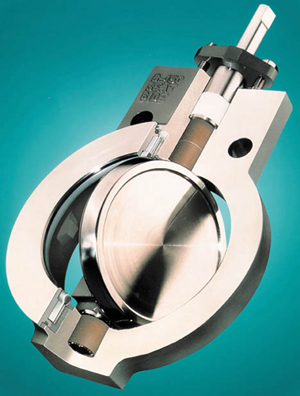

BX2001 High Performance Butterfly Valve

The BX2001 High Performance Butterfly Valve is a superior quality ASME Class 150 and 300 valve available in standard PFA, fire sealed and two metal seated versions. Offered in 2″ through 36″ sizes and in both wafer and lug body designs, all are available with a wide variety of packing options to meet your routine or most rigid service requirements.

Benefits:

- Broad application versatility via numerous design options: wafer and lug bodies; standard PFA, optional UHMWPE, fire-sealed, Apex® and TriFlex™ seated versions; and multiple packing options

- Reduced fugitive emissions through triple-leak protection of primary stem seal plus two optional secondary seals

- Increased capacity and improved flow control with low-profile, double-offset disc

- Improved personnel and plant safety per adherence to API 609 criteria for safe, reliable anti-blowout protection

Total Quality: The BX2001 High Performance Butterfly Valve is an ideal choice for precise throttling control or on-off service with lighter weight piping systems and less expensive, energy-efficient actuators. Offered in a vast selection of materials to excel in your chemical process.

World Class Valve Performance. All castings meet rigid ASTM standards. All BX2001 valves comply with ASME B16.34, ASME B16.5, ASME B16.10, MSS SP68, MSS SP61, API 598, API 607, API 609, and ISO 5752. All PFA seated valves and optional UHMWPE seated valves are tested in accordance with ASME B 16.34 and MSS SP61. No through or external leaks are allowed, thereby exceeding the shut-off requirements of ASME/FCI 70-2 for all classes. All Apex and TriFlex metal seated valves are tested to ASME/FCI 70-2 Class IV and VI leakage rates, respectively. All valves available in ASME Class 150 and 300; DIN PN 10, -16, -20, -25 and -40 drilling.

Flowserve offers a wide variety of seat design options to most cost-effectively suit your service requirements.

Standard PFA Seat: 400F

Fire-safe seat: Primary seat before fire -20F to 400F; High temperature Metal seat after fire 400F to 600F

UHMWPE (abrasion-resistant) seat -20 to 200F

APEX Metal seat (Class IV) 400F and 600F Ratings

Triflex metal seat (Class VI) in 400,600,800, and 1000F Configurations

Features

- UHMWPE Seats For Abrasive Services

- Apex Metal Seated Valves Inconel seat assures Class IV shut-off

- The fire sealed version BX2001 meets API 607 Requirements.

- TriFlex Metal Seated Valves for extended service life to 1000F (538C).

- Many BX2001 Packing Options for ASME Class 150 and 300 Valves

- Many BX2001 Packing Options for ASME Class 150 and 300 Valves

- Gibb-Key locks vane to shaft for unparalleled security.

BX2001 High Performance Butterfly Valve Brochure

BX2001 High Performance Butterfly Valve BrochureBX2001 High Performance Butterfly Valve IOM

BX2001 High Performance Butterfly Valve IOMContact our Valve Specialist Team:

Brendan Merrigan (External) – Mob: 087 2598124

Internal Team

Brian Barry – Tel: 021 461 7211

Darragh Rodgers- Tel: 021 461 7241

Miriam Adair- Tel: 021 461 7235

Ross O’Donovan – Tel: 021 461 7230

Shauna O’Connor – Tel: 021 461 7237

Tim Quigley – Tel: 021 461 7209

Vicki McGrath – Tel: 021 461 7207

Tel: 021 461 7200