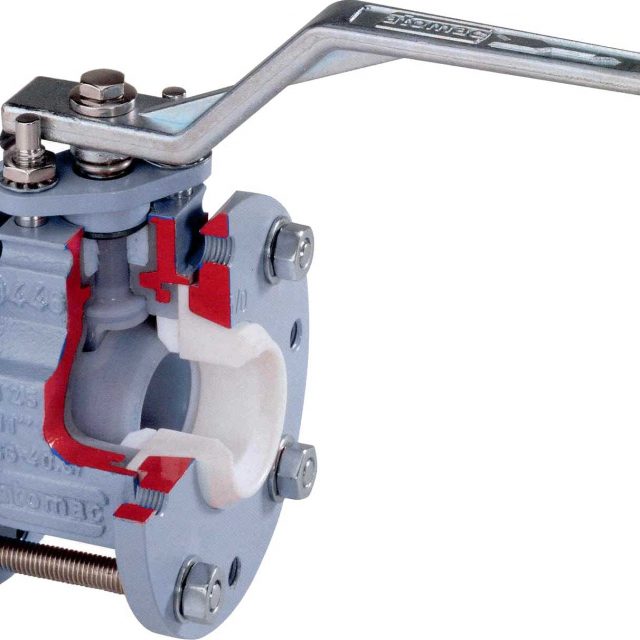

AKH7-KP Lined Ball Valves for Glass Pipe Systems

AKH7-KP Lined Ball Valves are easy to install in glass pipe systems with socket/ball or plane ends according to DIN/ISO 3587 and 4704. Molded fluorocarbon resin liners are made of either FEP or PFA, depending upon the application, for both long service and high corrosion resistance due to their uniform and blowhole-free thickness. The liners’ non-stick properties are also ideal for handling highly viscous fluids or for those process applications with high purity requirements. An Anti-static device protects against potentially dangerous electrostatic discharges. The stem is internally assembled to eliminate the possibility of a blowout. Long-term protection against atmospheric leakage is provided by PTFE chevron packing rings in the deep stuffing box and by the moulded liner/seal. For flange/glass end connections the AKH7-KPF is available. AKH7-KP Lined Ball Valves are also available with conductive material for the linings, seals and gland packings.

Industries:

Acid Transfer, Agriculture, Bleach Chemicals, Caustic and Chlor-Alkali, Water Treatment, Food Processing, Leaching Acid, Pharmaceuticals, Waste Processing, Chemical and Liquor.

Features

- For flange/glass end connections the AKH7-KPF is available.

- AKH7 valves are also available with conductive material for the linings, seals and gland packings.

- An Anti-static device protects against potentially dangerous electrostatic discharges.

- The stem is internally assembled to eliminate the possibility of a blowout.

- Long-term protection against external leakage to the atmosphere.

AKH7-KP Lined Ball Valves for Glass Pipe Systems Bulletin

AKH7-KP Lined Ball Valves for Glass Pipe Systems BulletinContact our Valve Specialist Team:

Brendan Merrigan (External) – Mob: 087 2598124

Internal Team

Brian Barry – Tel: 021 461 7211

Darragh Rodgers- Tel: 021 461 7241

Miriam Adair- Tel: 021 461 7235

Ross O’Donovan – Tel: 021 461 7230

Shauna O’Connor – Tel: 021 461 7237

Tim Quigley – Tel: 021 461 7209

Vicki McGrath – Tel: 021 461 7207

Tel: 021 461 7200