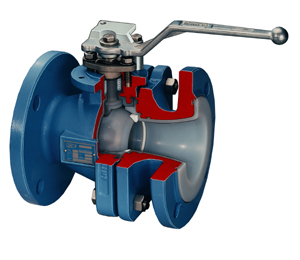

AKH3 Standard Port Lined Ball Valve

The AKH3 Standard Port Lined Ball Valve is an ASME dimensional valve that enables the replacement of present valves with no need to alter existing piping. 1 in (25 mm) through 12 in (300 mm). The AKH3 is an ANSI B16.10 short pattern, 150 lbs., reduced port, lined ball valve with a minimum cavity space. The floating ball design ensures bubble-tight shut-off across the pressure range of 1 mbar to 19 bar. Long-term protection against external leakage to atmosphere is provided by PTFE chevron packing rings in a deep stuffing box, the substantial body flanges and the moulded liner seal. An antistatic device provides protection against potentially dangerous electrostatic discharge and the anti blow-out safety stem design eliminates the possibility of a blow-out. Also available as V-port ball valve for precise modulating control services and various liner materials including conductive PFA.

AKH3 has ANSI Body dimensions. Thick liner is 100% spark-tested with 20,000 V, made from highly corrosion-resistant FEP. A variety of metallic and non-metallic ball material options are available.

Ductile iron body sections (ASTM A39560-40-18) with high strength B7 fasteners are both robust and rigid. B8 bolting is offered as an alternate. Designed in accordance with ASME B16.5, Class 150 flange dimensions and ASME B16.10 face-to-face dimensions. Leak testing according to API598.

Industries:

Caustic and Chlor-Alkali, Chemical and Liquor, Food Processing, Leaching Acid, Bleach Chemicals, Waste Processing, Water Treatment, Acid Transfer, Agriculture, Pharmaceuticals.

Flowserve is the world’s leader in the design and manufacture of corrosion resistant fluoropolymer lined valves. Flowserve Atomac valves provide bubble-tight shutoff, low maintenance, no-leak stem seals, and the safety assurance of a blowout-proof stem assembly. For performance, safety, and reliability, Atomac is the valve of choice.

Features

- Lining securely locked into the body by T slots and locking grooves; completely encapsulated ball and stem.

- PTFE chevron packing provides stem seal integrity while maintaining low turning torque.

- Anti-blowout stem assembly prevents stem blowout

- ISO 5211 universal mounting pad permits easy automation even with the valve in the pipeline

- Characterized ball available for throttling applications

- Stem Extensions Allow for insulation of valve

AKH3 Standard Port Lined Ball Valve Bulletin

AKH3 Standard Port Lined Ball Valve BulletinContact our Valve Specialist Team:

Brendan Merrigan (External) – Mob: 087 2598124

Internal Team

Brian Barry – Tel: 021 461 7211

Darragh Rodgers- Tel: 021 461 7241

Miriam Adair- Tel: 021 461 7235

Ross O’Donovan – Tel: 021 461 7230

Shauna O’Connor – Tel: 021 461 7237

Tim Quigley – Tel: 021 461 7209

Vicki McGrath – Tel: 021 461 7207

Tel: 021 461 7200