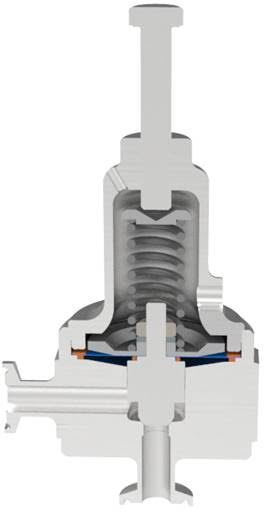

3171 Back Pressure Relief Regulator

The 3171 is a stainless steel back pressure relief regulator designed to handle small to mid-capacity flow rates in sanitary biotechnical process piping systems.

This unit is capable of control ling inlet pressure to a level between 5 and 200 psig (.34 and 13.8 Barg).

Trim Removal: Easily removable trim from regulator while in-line. Materials Construction: All metallic parts are SST. Unit is cleaned to Cashco Spec. #S-1576.

Surface Finish: Interior of body surface electro polished to #32 micro-inch Ra finish with electro-polished exterior.

Widely applied for processed food production — confectionary, beverages, nutritional supplements and artificial sweeteners.

May also be used in cosmetics production and specialty chemicals. Would be found supporting fermenters, batching tanks, cookers, dryers and other similar equipment.

Size: 1/2″ (DN15)

Operating Temperature: -20 to +400°F (-29° to +205°C)

Inlet Pres sure:240 psig (16.5 Barg) maximum

Features:

High Stability: High mass plug allows dampening of high frequency disturbances from inlet or outlet side of regulator.

Applications:

Used in pharmaceutical industry in production of many health care products for both human and animal consumption.

IOM

IOMTechnical Specification

Technical Specification