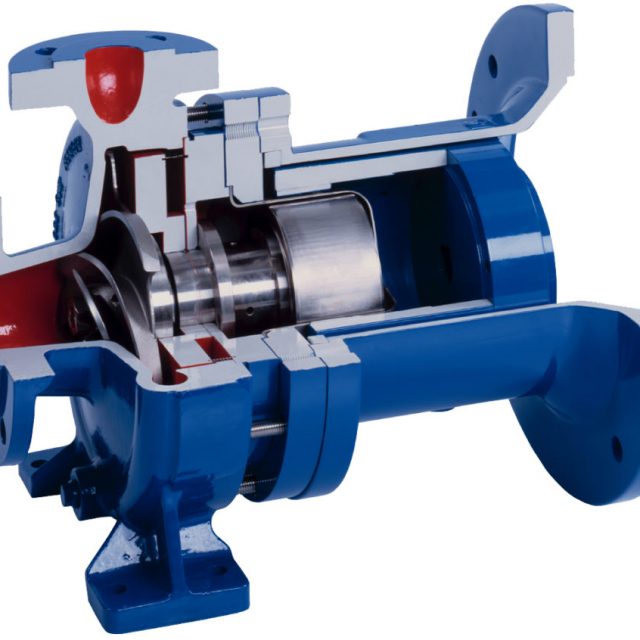

SIHI ISOchem Pump CBE

SIHI ISOchem Pump CBE is a horizontal, single-stage volute casing pumps with dimensions to DIN EN ISO 2858. They meet the technical requirements of EN ISO 5199. It is a modular configuration of either bare shaft end or close-coupled design. This modular process pump consists of hydraulics with closed impellers. Due to the modular configuration, the pumps can be used in a bare shaft or close-coupled configuration. Shaft sealing options are single or double acting mechanical seals, magnetic drives or canned motor designs. The benefits are the interchangeability of the back pull-out assemblies and a reduction of spare parts costs.

The SIHI ISOchem Pump CBE range of pumps meet the requirements on custom-built solutions in the process industry, in the following areas:

- Chemical

- Food processing

- Plant engineering and construction

- Pharmaceutical

- Petrochemical

- Paper

- Plastic

Technical Data:

- Flow rate: max. 650 m³/h

- Head: max. 150 m

- Speed: max. 3600 min-1

- Materials: Cast iron, cast steel, stainless steel, Hastelloy, duplex

- Temperature: max. 400 °C Casing pressure: max. 25 bar

- Shaft seal: Mechanical seal or magnetic coupling Dimensions of according to DIN or ANSI flanges: (see flanges)

- Direction of Rotation: clockwise, when viewed from rotation drive end

The SIHI ISOchem Pump CBE is a modular configuration of either bare shaft end or close-coupled design. Shaft sealing options are single or double-acting mechanical seals or magnetic couplings. The benefits are the interchangeability of the back pull-out assemblies and the reduction of spare parts cost.

Benefits:

- Temperature range: -40°C up to +400 °C. No cooling required.

- Impeller secured with key and nut – no possibility of damage if the rotation is incorrect.

- An integral strainer is standard for the reliable handling of solids.

- Robust product lubricated SiC bearing assembly – reliable even under adverse operating conditions. Radial and axial lubrication grooves improve dry running properties.

- Deep drawn Hastelloy containment shell – low drive losses, no welding used, very high-pressure rating.

- No O-rings in contact with pumpage – no compatibility or purity issues.

- Provision for PT100 is standard for temperature monitoring and dry run protection.

- Pumps are close-coupled as standard. No time-consuming alignment is required. Alignment of pump and motor is unaffected by temperature swings.

- Enclosed impeller with balance holes is standard – effects of axial thrust are reduced for increased reliability.

- Built-in safety clearance prevents rupture of containment shell in the event of bearing failure.

- Large installed population base.

Download SIHI ISOchem Pump CBE Brochure

Download SIHI ISOchem Pump CBE BrochureDownload SIHI ISOchem Pump CBE Range Coverage, 50 Hz

Download SIHI ISOchem Pump CBE Range Coverage, 50 HzDownload SIHI ISOchem Pump CBE Range Coverage, 60 Hz

Download SIHI ISOchem Pump CBE Range Coverage, 60 HzContact our Pump Specialist Team:

Phil Soltan (External) – Mob: 086 185 3782

Internal Team

Adrian McSweeney – Tel: 021 461 7212

Paul-Fox Morris – Tel: 021 461 7231

Una Long (Pump & Service Support) – Tel: 021 431 7232

Tel: 021 461 7200